STRAUB-METAL-GRIP

STRAUB-METAL-GRIP pipe couplings are axially tension-resistant pipe connections for all metallic pipes and rigid plastic pipes.

The universal connection solution offers countless application possibilities on almost all pipe systems.

The installation is carried out on smooth-surfaced pipes without any pipe end machining.

The compact design allows pipe routing in the smallest of spaces. Unexpected secondary stresses, as well as inaccuracies in the pipe routing caused by the customer, are absorbed by the couplings due to the flexible design. This allows a simple and quick installation, which results in noticeable cost savings.

METAL-GRIP ø 30.0 - 219.1 mm

| adMm | Clamping range [mm] | PN industry [bar] | PN shipbuilding [bar] | B [mm] | DV [mm] | C [mm] | X [mm] | R without strip insert [mm] | R with strip insert [mm] | Torque rate [Nm] | Allen head [mm] | Thread metric |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 29.5 - 30.5 | 67 | 16 | 46/67 | 47 | 18 | 56 | 5 | 5 | 10 | 6 | 8 |

| 33.7 | 33.2 - 34.2 | 62 | 16 | 46/67 | 52 | 18 | 63 | 5 | 5 | 10 | 6 | 8 |

| 38 | 37.5 - 38.5 | 58 | 16 | 61 | 58 | 19 | 73 | 5 | 5 - 10 | 15 | 6 | 8 |

| 42.4 | 41.9 - 42.9 | 53 | 16 | 61 | 62 | 20 | 76 | 5 | 5 - 10 | 15 | 6 | 8 |

| 44.5 | 44.0 - 45.0 | 48 | 16 | 61 | 64 | 20 | 80 | 5 | 5 - 10 | 15 | 6 | 8 |

| 48.3 | 47.8 - 48.8 | 44 | 16 | 61 | 68 | 20 | 83 | 5 | 5 - 10 | 15 | 6 | 8 |

| 54 | 53.5 - 54.5 | 39 | 16 | 77 | 74 | 38 | 89 | 5 | 5 - 10 | 15 | 6 | 8 |

| 57 | 56.4 - 57.6 | 37 | 16 | 77 | 77 | 32 | 92 | 5 - 15 | 5-25 | 15 | 6 | 8 |

| 60.3 | 59.7 - 60.9 | 37 | 16 | 77 | 82 | 32 | 95 | 5 - 15 | 5-25 | 15 | 6 | 8 |

| 63.5 | 62.9 - 64.1 | 37 | 16 | 77 | 84 | 32 | 98 | 5 - 15 | 5-25 | 15 | 6 | 8 |

| 73 | 72.2 - 73.8 | 56 | 16 | 94 | 95 | 39 | 117 | 5 - 15 | 5-25 | 35 | 8 | 10 |

| 76.1 | 75.3 - 76.9 | 56 | 16 | 94 | 100 | 39 | 117 | 5 - 15 | 5-25 | 35 | 8 | 10 |

| 84 | 83.2 - 84.8 | 45 | 16 | 94 | 112 | 39 | 123 | 5 - 15 | 5-25 | 35 | 8 | 10 |

| 88.9 | 88.0 - 89.8 | 41 | 16 | 94 | 117 | 39 | 123 | 5 - 15 | 5-25 | 35 | 8 | 10 |

| 104 | 103.0 - 105.0 | 37 | 16 | 94 | 133 | 39 | 151 | 5 - 15 | 5-25 | 35 | 8 | 10 |

| 108 | 106.9 - 109.1 | 35 | 16 | 94 | 133 | 39 | 151 | 5 - 15 | 5-25 | 35 | 8 | 10 |

| 114.3 | 113.2 - 115.4 | 34 | 16 | 94 | 139 | 39 | 157 | 5 - 15 | 5-25 | 35 | 8 | 10 |

| 129 | 127.7 - 130.3 | 33 | 16 | 108 | 160 | 43 | 182 | 5 - 15 | 5-25 | 60 | 10 | 12 |

| 133 | 131.7 - 134.3 | 33 | 16 | 108 | 160 | 43 | 182 | 5 - 15 | 5-25 | 60 | 10 | 12 |

| 139.7 | 138.3 - 141.1 | 32 | 16 | 109 | 168 | 43 | 191 | 5 - 15 | 5-25 | 60 | 10 | 12 |

| 154 | 152.5 - 155.5 | 32 | 16 | 109 | 186 | 51 | 210 | 5 - 15 | 5-25 | 60 | 10 | 12 |

| 159 | 157.4 - 160.6 | 31 | 16 | 109 | 187 | 43 | 210 | 5 - 15 | 5-25 | 60 | 10 | 12 |

| 168.3 | 166.6 - 170.0 | 29 | 16 | 109 | 200 | 43 | 220 | 5 - 15 | 5-25 | 60 | 10 | 12 |

| 219.1 | 216.9 - 221.3 | 26 | 16 | 150 | 259 | 60 | 288 | 5 - 15 | 5-25 | 100 | 14 | 16 |

Remarks:

- Follow fitting instructions

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- The pressure values are valid on radial rigid carbon steel pipes under static loads

- Strip inserts are optional accessories

- Additional sealing sleeves and temperature ranges on request

- Follow fitting instructions

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- The pressure values are valid on radial rigid carbon steel pipes under static loads

- Strip inserts are optional accessories

- Additional sealing sleeves and temperature ranges on request

METAL-GRIP ø 180.0 - 609.6 mm

| adMm | Clamping range [mm] | PN industry [bar] | PN shipbuilding [bar] | B [mm] | DV [mm] | C [mm] | X [mm] | R without strip insert [mm] | R with strip insert [mm] | Torque rate [Nm] | Allen head [mm] | Thread metric |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 180 | 178.0 - 182.0 | 29 | 16 | 148 | 225 | 67 | 256 | 5 - 15 | 5-35 | 150 | 17 | 20 |

| 193.7 | 192.0 - 195.5 | 29 | 16 | 148 | 239 | 67 | 270 | 5 - 15 | 5-35 | 150 | 17 | 20 |

| 200 | 198.0 - 202.0 | 28 | 15 | 148 | 245 | 67 | 276 | 5 - 15 | 5-35 | 180 | 17 | 20 |

| 206 | 204.0 - 208.0 | 28 | 15 | 148 | 251 | 67 | 282 | 5 - 15 | 5-35 | 180 | 17 | 20 |

| 244.5 | 242.0 - 247.0 | 27 | 14 | 148 | 290 | 67 | 330 | 5 - 15 | 5-35 | 180 | 17 | 20 |

| 267 | 264.5 - 269.5 | 24 | 12 | 148 | 312 | 67 | 352 | 5 - 15 | 5-35 | 180 | 17 | 20 |

| 273 | 270.5 - 275.5 | 21 | 12 | 148 | 318 | 67 | 359 | 5 - 15 | 5-35 | 180 | 17 | 20 |

| 323.9 | 320.5 - 327.0 | 18 | 10 | 148 | 369 | 67 | 411 | 5 - 15 | 5-35 | 230 | 17 | 20 |

| 355.6 | 352.0 - 359.0 | 17 | 8 | 148 | 401 | 67 | 444 | 5 - 15 | 5-35 | 230 | 17 | 20 |

| 406.4 | 402.5 - 410.5 | 14 | 8 | 148 | 451 | 67 | 494 | 5 - 15 | 5-35 | 230 | 17 | 20 |

| 457.2 | 452.5 - 462.0 | 8 | 6 | 148 | 502 | 67 | 546 | 5 - 15 | 5-35 | 250 | 17 | 20 |

| 508 | 503.0 - 513.0 | 6 | 5 | 148 | 553 | 67 | 598 | 5 - 15 | 5-35 | 250 | 17 | 20 |

| 558.8 | 554.0 - 564.0 | 6 | 4.5 | 148 | 604 | 67 | 649 | 5 - 15 | 5-35 | 300 | 17 | 20 |

| 609.6 | 604.5 - 614.5 | 5 | 4 | 148 | 655 | 67 | 701 | 5 - 15 | 5-35 | 300 | 17 | 20 |

Remarks:

- Follow fitting instructions

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- The pressure values are valid on radial rigid carbon steel pipes under static loads

- Strip inserts are optional accessories

- Additional sealing sleeves and temperature ranges on request

- Follow fitting instructions

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- The pressure values are valid on radial rigid carbon steel pipes under static loads

- Strip inserts are optional accessories

- Additional sealing sleeves and temperature ranges on request

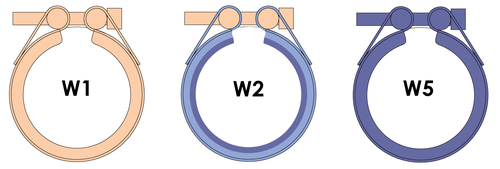

STRAUB pipe couplings are made of the same or different materials depending on the diameter and size. The following overview shows the details. If you have any questions, please contact our application engineering department.

METAL-GRIP ø 30.0 - 219.1 mm

| Components | W1 | W2 | W5 |

|---|---|---|---|

| Casing | - | AISI 316 L | AISI 316 L or similar |

| Bolts | - | AISI 4135 | A4 - 80 |

| Bars | - | AISI 12L14, galvanised | AISI 316 L or similar |

| Anchoring rings | - | AISI 301 | AISI 301 |

| Strip insert (option) | - | AISI 316 L or similar / PVDF | AISI 316 L or similar / PVDF |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|

| EPDM | -20 °C up to +100 °C | all qualities of water, waste water, air, solids and chemical products |

| NBR | -20 °C up to +80 °C | water, gas, oil, fuel and other hydrocarbons |

METAL-GRIP ø 180.0 - 609.6 mm

| Components | W1 | W2 | W5 |

|---|---|---|---|

| Casing | AISI A738, hot-dip galvanised | - | - |

| Bolts | AISI 4135 | - | - |

| Bars | AISI 12L14, galvanised | - | - |

| Anchoring rings | AISI 301 | - | - |

| Strip insert (option) | AISI 316 L or similar / PVDF | - | - |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|

| EPDM | -20 °C up to +100 °C | all qualities of water, waste water, air, solids and chemical products |

| NBR | -20 °C up to +80 °C | water, gas, oil, fuel and other hydrocarbons |