STRAUB-REP-FLEX

The coupling for the reliably repairing of laterally broken pipes, cracks and the leakage of pipes caused by corrosion.

The STRAUB-REP-FLEX is intended to be used for the fast and reliably repairing of broken pipes and the leakage of water/drinking water pipes, as well as gas- and oilpipes caused by corrosion.

The proven STRAUB sealing lip system provides dependable and durable application on pipes of various materials such as steel, cast iron, ductile cast iron, fibre cement, PVC or PE. In addition, two different materials of the same DN can be connected using STRAUB-REP-FLEX.

REP-FLEX DN 40 - DN 150 | Boverall Lenght 200 and 300 mm

| DN | Clamping range [mm] | Overall length [mm] | PN [bar | Torque rate [Nm] | C [mm] | Cast iron [mm] | Old cast iron [mm] | Steel [mm] | PE [mm] | Allen head [mm] | Thread metric |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 46 - 53 | 200 | 16 | 10 | 142 | - | 51 - 53 | 46.0 - 49.0 | 50 | 17 | 10 |

| 40 | 53 - 60 | 200 | 16 | 10 | 142 | 56 | - | - | - | 17 | 10 |

| 50 | 56 - 64 | 200 | 16 | 10 | 142 | - | 62 - 64 | 56.0 - 61.0 | 63 | 17 | 10 |

| 50 / 60 | 63 - 71 | 200 | 16 | 10 | 142 | 66 | - | 70.0 - 71.0 | - | 17 | 10 |

| 60 / 65 | 72 - 80 | 200 | 16 | 10 | 142 | 77 | 72 - 74 | 72.0 - 76.1 | 75 | 17 | 10 |

| 65 / 70 | 76 - 83 | 200 | 16 | 10 | 142 | 82 | - | 77.0 - 79.0 | - | 17 | 10 |

| 70 | 82 - 89 | 200 | 16 | 10 | 142 | 87 | 83 - 85 | - | - | 17 | 10 |

| 80 | 88 - 98 | 200 | 16 | 10 | 142 | 98 | 94 - 96 | 88.0 - 89.0 | 90 | 17 | 10 |

| 90 | 97 - 108 | 200 | 16 | 10 | 142 | 108 | 104 - 108 | 97.0 - 102.0 | - | 17 | 10 |

| 100 | 108 - 118 | 200 / 300 | 16 | 10 | 142 / 245 | 118 | 114 - 116 | 107.0 - 114.3 | 110/125 | 17 | 10 |

| 100 | 120 - 130 | 200 / 300 | 16 | 10 | 142 / 245 | - | 123 - 125 | - | - | 17 | 10 |

| 100 / 125 | 128 - 138 | 200 / 300 | 16 | 10 | 142 / 245 | - | 134 - 137 | 132.0 - 134.0 | - | 17 | 10 |

| 125 | 139 - 149 | 200 / 300 | 16 | 10 | 142 / 245 | 144 | 140 - 143 | 139.7 | 140 | 17 | 10 |

| 135 / 150 | 150 - 160 | 200 / 300 | 16 | 10 | 142 / 245 | - | 150 - 153 | 157.0 - 160.0 | 160 | 17 | 10 |

Remarks:

- Follow fitting instructions

- Test pressure = PN x 1.5

- Assembly on pipes can be of various materials

- Follow fitting instructions

- Test pressure = PN x 1.5

- Assembly on pipes can be of various materials

REP-FLEX DN 150 - DN 400 | Overall Lenght 300 mm

| DN | Clamping range [mm] | Overall length [mm] | PN [bar | Torque rate [Nm] | C [mm] | Cast iron [mm] | Old cast iron [mm] | Steel [mm] | PE [mm] | Allen head [mm] | Thread metric |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 150 | 159 - 170 | 300 | 16 | 20 | 212 | 170 | 166 - 169 | 168.3 | 160 | 19 | 12 |

| 165 | 175 - 185 | 300 | 16 | 20 | 212 | - | 180 - 184 | - | - | 19 | 12 |

| 175 | 186 - 196 | 300 | 16 | 20 | 212 | 196 | 191 - 194 | 183.0 - 191.0 | - | 19 | 12 |

| 175 / 180 | 196 - 206 | 300 | 16 | 20 | 212 | - | 198 - 200 | - | 200 | 19 | 12 |

| 190 / 200 | 206 - 216 | 300 | 16 | 20 | 212 | - | 208 - 211 | 211.0 - 216.0 | - | 19 | 12 |

| 200 | 216 - 226 | 300 | 16 | 20 | 212 | 222 | 218 - 222 | 219.1 | 225 | 19 | 12 |

| 225 | 241 - 251 | 300 | 16 | 20 | 212 | 248 | 244 - 247 | 241.0 | 250 | 19 | 12 |

| 250 | 264 - 274 | 300 | 16 | 20 | 212 | 274 | 268 - 273 | 264.0 - 273.0 | - | 19 | 12 |

| 250 | 274 - 284 | 300 | 16 | 20 | 212 | - | - | - | 280 | 19 | 12 |

| 300 | 315 - 325 | 300 | 10 | 20 | 212 | 324 | 322 - 325 | 316.0 - 323.9 | 315 | 19 | 12 |

| 350 | 355 - 365 | 300 | 10 | 20 | 212 | - | - | 355.6 | 355 | 19 | 12 |

| 350 | 368 - 379 | 300 | 10 | 20 | 212 | 378 | 376 - 379 | 368.0 | - | 19 | 12 |

| 400 | 398 - 408 | 300 | 10 | 20 | 212 | - | - | 406.4 | 400 | 19 | 12 |

| 400 | 419 - 429 | 300 | 10 | 20 | 212 | 429 | 426 - 430 | 419.0 | - | 19 | 12 |

Remarks:

- Follow fitting instructions

- Test pressure = PN x 1.5

- Assembly on pipes can be of various materials

- Follow fitting instructions

- Test pressure = PN x 1.5

- Assembly on pipes can be of various materials

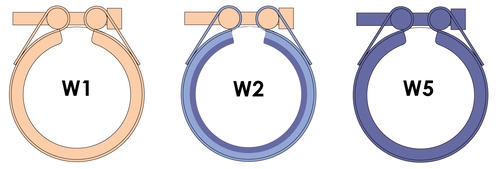

STRAUB pipe couplings are made of the same or different materials depending on the diameter and size. The following overview shows the details. If you have any questions, please contact our application engineering department.

| Components | Materials |

|---|---|

| Sealing sleeve | Temperatur | Medium |

|---|---|---|