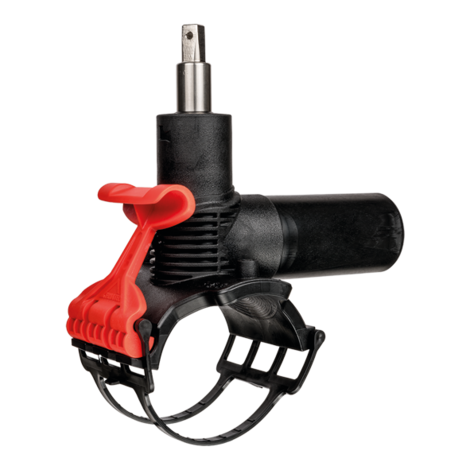

Βαλβίδες πίεσης με μακριά έξoδο και μοχλό σύσφιξης RED SNAP

Compact fitting in HD-PE with no threaded connection. Actuating spindle in stainless steel 1.4305. No re-insulating required. Leak free and swarfless tapping up to 10 bar (gas) or 16 bar (water). Integral drill with upper and lower stop, guided in a metal sleeve. Max. 9 turns to activate “OPEN/CLOSE”.

A complete tool-free mounting of the saddle by innovative fast clamping system (RED SNAP). By new design, 50 % of total installation time can be saved.

With exposed heating element for optional heat transfer. Maintenance free, operating isolating valve actuated by a rod (e.g. FRIALEN EBS). Length of the outlet spigots dimensioned for 2 fusion operations. Four cornered shaft wrench size 14 mm.

Compact fitting in HD-PE with no threaded connection. Actuating spindle in stainless steel 1.4305. No re-insulating required. Leak free and swarfless tapping up to 10 bar (gas) or 16 bar (water). Integral drill with upper and lower stop, guided in a metal sleeve. Max. 9 turns to activate “OPEN/CLOSE”.

A complete tool-free mounting of the saddle by innovative fast clamping system (RED SNAP). By new design, 50 % of total installation time can be saved.

With exposed heating element for optional heat transfer. Maintenance free, operating isolating valve actuated by a rod (e.g. FRIALEN EBS). Length of the outlet spigots dimensioned for 2 fusion operations. Four cornered shaft wrench size 14 mm.

Areas of Application

The FRIALEN-Pressure Tapping Valves DAV are used for branches of unpressurised and pressurised gas and water pipelines. Outlet spigots are prepared for integration of excess flow valves.

Assembly Instructions

The fusion of the HD-PE distribution pipes and the service pipes with FRIALEN-Pressure Tapping Valves takes place by FRIALEN-fusing – leakproof and longitudinally strong.

The saddle and the outlet spigot have to be prepared according to the general assembly instructions (see “Assembly Instructions” for “FRIALEN-Safety Fittings for house service and supply pipes up to d 225”). This involves removing the oxide layer and cleaning the pipe surface covered by the saddle as well as the outlet spigot and the pipe end.

The assembly of the pressure tapping valve with fast clamping mechanism takes place within seconds with the fast clamping lever RED SNAP without additional tools.

For „Open/Close” the pressure tapping valve require 8 to 9 turns, depending to the dimension and design, by using an operating key type E according to DIN 3223.

(The tapping process need less turns, because of the intermediate position of the drill in supplied condition).

Good reasons for using the FRIALEN Pressure Tapping Valves DAV with fast clamping lever RED SNAP:

Compact part, solid injection molded body made from HD-PE

Simple and reliable assembly without any tool, thanks to the patented fast clamping lever RED SNAP

The flexible saddle compensates pipe tolerances and provides always an optimal, uniform buildup of melt pressure during the fusion

Fusing and tapping of the main under maximum permitted operating pressure gas/water

Simple start-up of the pressure tapping valve because of little tapping forces

No preventive measures necessary with regard to corrosion

Actuating spindle made from corrosion-resistant steel

Swarfless tapping due to rotating punching drill made of stainless steel

Punched-out pipe piece fits securely and permanent in the drill

Drill with solid upper and lower stop

Length of outlet spigot dimensioned for two fusion operations

Barcode exposed on fast clamping lever RED SNAP for easy scanning with readerwand or barcode scanner

Installation set DBS (EBS) is continuously telescopic and self supported in any extended position

Installation set with a sleeve tube bell with integrated locking function: connects the installation kit firmly to the DAV, unintentional release is prevented

A foam rubber ring in the sleeve tube bell prevents dirt from penetrating into the installation set

Subsequent tapping with the installation set DBS (EBS) from the surface box is possible

High torques can be transferred because of a solid construction