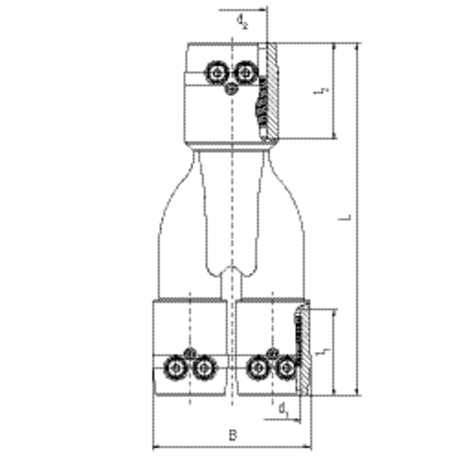

Ηλεκτροσύνδεση (Τύπου Υ)

Ηλεκτροσύνδεση (Τύπου Υ) με 3 ενσωματωμένους ηλεκτροσυνδέσμους με εκτεθειμένες, σταθερές αντιστάσεις θέρμανσης για άμεση μεταφορά θερμότητας στον σωλήνα.

Pipe junction (Y piece) in a compact design with 3 integrated couplers with exposed, fixed heating coils for direct heat transfer to the pipe.

PE 100 SDR 11

Maximum working pressure 16 bar (water)/10 bar (gas)

| Κωδικός προϊόντος | d | BX | PU | t1 | t2 | B | Weight kg |

|---|---|---|---|---|---|---|---|

| 640034 | 32-32-40 | 28 | 504 | 50 | 56 | 92 | 0,230 |

| 640036 | 40-40-50 | 18 | 324 | 56 | 60 | 115 | 0,360 |

The FRIALEN Geo Y can be fused with pipes made of PE 100, PE 100 Plus Geo CR respectively PE 100-RC of SDR stages 11 to 17.6.

SKZ Mark A 500 (SKZ HR 3.26)

Area of application

The FRIALEN Y-pieces are used for the connection of FRIALEN borehole heat exchanger pipes to be able to operate two or more circuits via a shut-off element or to quickly and efficiently create a direct connection to the heat pump. FRIALEN Y-pieces have a smooth, hydraulically optimised internal contour for optimal flow conditions.

Assembly instructions

The connection of the pipes with FRIALEN Y-pieces made by FRIALEN electrofusion is leak-proof and longitudinally strong.

The PE spigot end of the YS-pieces as well as the borehole heat exchangers- and connection pipes, made of PE 100 or PE 100 plus Geo CR respectively PE 100-RC, get prepared (removing oxide layer/cleaning), according to the general assembly instructions (see “Assembly Instructions” for “FRIALEN-Safety Fittings for house connections and distribution pipes up to d 225”) and can be used for example with a FRIALEN elbow 90°.

Many good reasons for using the FRIALEN Y-pieces:

8 mm coupler extension of the Y-piece for more safety when installing coiled pipe because of long guiding- and holding zones

less space required thanks to compact design

reduces installation time thanks to integrated fusion couplers giving simultaneously processing safety

leak-proof, longitudinally strong connection

exposed, fixed heating coil for direct heat transfer to the pipe

maximum stability through great wall thickness

fusion indicators for visual fusion control

barcode for fully automatic fusion with HDPE pipes from SDR stages 11 to 17.6, taking into consideration the ambient temperature (temperature compensation)

flexible use enabled due the variation of either Y-piece (3 x coupler) or YS-piece (2 x coupler,1 x spigot end)

additional barcode for tracing back the component part (Traceability-Coding)

durable batch marking

individual foil wrap to prevent dirtying at building site

touch proof electric contacts

small annular gap for build-up of optimum joining pressure in the fusion zone