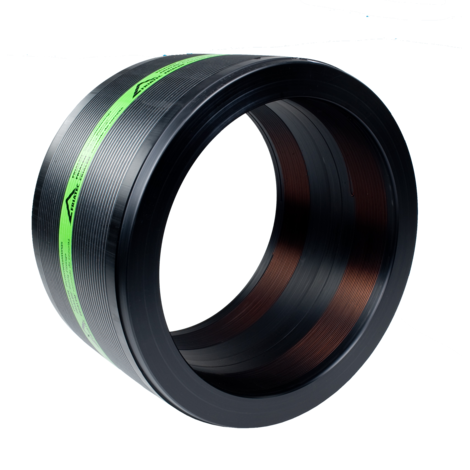

Coupler without inner stop, SDR 17

Coupler UB SDR 17 without inner stop

- Gas and water

- Working pressure: MOP (gas) 5 bar, PFA (water) 10 bar

- Material: PE 100

- Safety technology

- Separate fusion zone from d 400

- Large insertion depth for good pipe routing (no holding devices required)

- DVGW test mark: DV-8611AU2250 and DW-8610CN0420

Note

From nominal size 560 with preheating technology and from nominal size 1000, only one FRIAMAT XL is to be utilised, which is available as a loan device under Order No. 613091.

PE 100 SDR 17

Maximum permissible working pressure 10 bar (water) / 5 bar (gas)

| Reference | d | BX | PU | D | L | t | h | B | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|

| 616529 | 315 | 1 | 18 | 356 | 280 | 140 | 72 | 358 | 5,880 |

| 616530 | 355 | 1 | 18 | 400 | 290 | 145 | 70 | 402 | 7,600 |

| 616531 | 400 | 1 | 9 | 450 | 300 | 150 | 78 | 452 | 10,100 |

| 616532 | 450 | 1 | 4 | 506 | 320 | 160 | 87 | 508 | 13,650 |

| 616533 | 500 | 1 | 4 | 562 | 350 | 175 | 85 | 564 | 18,250 |

| 615706 | 560 | 1 | 2 | 630 | 380 | 190 | 77 | 632 | 24,800 |

| 615726 | 630 | 1 | 2 | 710 | 420 | 210 | 101 | 712 | 34,870 |

| 615994 | 710 | 1 | 2 | 800 | 442 | 221 | 112 | 802 | 47,500 |

| 616290 | 800 | 1 | 1 | 900 | 500 | 250 | 137 | 902 | 65,900 |

| 616345 | 900 | 1 | 1 | 1024 | 500 | 250 | 110 | 1026 | 91,500 |

| 616403 | 1000 | 1 | 1 | 1130 | 610 | 305 | 129 | 1132 | 121,000 |

| 616416 | 1200 | 1 | 1 | 1356 | 670 | 335 | 155 | 1358 | 205,000 |

Please note the mandatory labels directly on the product. DVGW test marks issued:

DV-8611AU2250 and DW-8610CN0420

Areas of Application

The FRIALEN-Coupler UB is used for cut and lay pipe connections.

Additional areas of application:

- Integration of adapters into an existing pipeline

- Connection of pipelines with fixed or restraint points

- Reinforcement / sealing of localised pipe damage

- Reinforcement of pinch points on small dimensions

Assembly Instructions

The fusion of pipe ends with the FRIALEN-Coupler UB takes place using FRIALEN-fusing – leakproof and longitudinally strong.

The pipe ends are prepared according to the general installation instructions (see “Assembly Instructions” for “FRIALEN-Safety Fittings for house connections and distribution pipes up to d 225” and “FRIALEN-Special Technology for laying large bore pipes and relining pipe networks”). This involves removing the oxide skin and cleaning the pipe ends. Please note that spigot of valves must be at least half as long as the coupler.

To compensate a larger annular gap (> 1 mm, max. 3 mm) between coupler and pipe, the pre-heating barcode can be used for couplers UB from d 560 (see instructions packed up with the coupler). Preheating is already integrated in the two-phase fusion process of the couplers UB-XL from d 1000.

For removal of the oxide layer, FWSG scraper tools are available which facilitate a uniform swarf removal and a reproducible quality of the fusion area preparation.

For large couplers UB-XL from d 1000, the powerful fusion unit FRIAMAT XL is to be used. The FRIAMAT XL is an all-purpose unit and operates with an input voltage of 400V, output voltage of max. 80V.

Good reasons for using the FRIALEN-Slide-over Coupler UB:

- Large coupler depth for ease of pipe guiding (no holding clamps required)

- Extra wide fusion zones

- Maximum stability through great wall thickness

- Cold zones at the front side and in the middle of the coupler

- Exposed heating coil for direct heat transmission to the pipe

- Small annular gap for build-up of optimum joining pressure in the fusion zone

- Touch proof electric contacts

- Fusion indicators for visual fusion control

- From d 560: pre-heating technique for a optimal gap-bridging

- From d 315: External reinforcement for an ideal fusion pressure

- Durable batch marking

- Individually wrapped for dirt protection

- Additional barcode for tracing back the fitting (Traceability-Coding).

get_app

get_app

get_app

get_app