Elbow 11° with spigot, SDR 11

Elbow WS11 SDR 11 with spigot

- Gas, water and H2

- Working pressure: MOP (gas) 10 bar, PFA (water) 16 bar

- Material: PE 100

- Angle 11 degrees

- Universal direction alteration

- Multiple combination = elbow 22 degrees and 33 degrees can be implemented

- Safety technology

- DVGW test mark: DV-8606AU2249

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water) / 10 bar (gas)

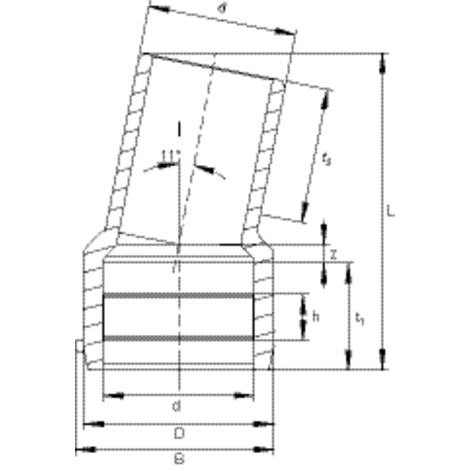

| Reference | d | BX | PU | D | t1 | t2 | z | h | B | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| 616139 | 110 | 8 | 144 | 141 | 79 | 82 | 14 | 32 | 151 | 0,920 |

| 616140 | 125 | 5 | 90 | 160 | 84 | 87 | 15 | 34 | 168 | 1,260 |

| 616141 | 160 | 8 | 64 | 200 | 93 | 98 | 20 | 50 | 206 | 2,270 |

| 616142 | 180 | 4 | 32 | 226 | 100 | 105 | 22 | 50 | 230 | 3,070 |

| 616143 | 225 | 1 | 18 | 280 | 114 | 120 | 24 | 50 | 284 | 5,290 |

FRIALEN safety fittings can be fused with pipes with SDR levels 11 to 17.6.

Other SDR levels available on request.

Please note the mandatory labels directly on the product.

DVGW test mark issued: DV-8606AU2249

Areas of Application

The FRIALEN Elbow WS 11° is designed for universal direction changes in HD-PE pipes even in restricted spaces. Multiple applications allow 22°, 33° etc … elbows to be reached.

Assembly Instructions

Fusing the pipe ends to the FRIALEN Elbow WS 11° takes place by the FRIALEN fusing – leakproof and longitudinal strong. One of the pipe ends is inserted in the coupler side of the FRIALEN Elbow WS 11° and then fused, the other pipe end is connected and fused to a FRIALEN Coupler. The pipe ends are prepared (remove oxide skin and cleaning) according to the general installation instructions (see also „Assembly Instructions” for „FRIALEN Safety Fittings for house connections and distribution pipes up to d 225”).

Good reasons for using the FRIALEN Elbow WS 11°:

- Universal direction changes due to multiple applications 11°/22°/33° or 45° + 11° …

- Maximum flexibility in case of obstructions and in restricted spaces due to coupler/spigot design

- Long insertion depth of coupler for optimum pipe guidance (no holding device required)

- Extra wide fusion zone inside coupler

- Maximum stability due to large wall thickness

- Cold zones at the front and in the centre of the coupler

- Exposed heating coil for direct heat transfer to pipe

- Small annular gap resulting in optimum joining pressure in the fusion zone

- Contacts safe to touch

- Fusion indicator for visual fusion control

- Additional barcode for tracing back the underground fitting (Traceability-Coding)

get_app

get_app

get_app

get_app