Fixation for absorbing axial thrust and tensile forces

Fixation for absorbing axial thrust and tensile forces FIXBLOC

- For the production of a fixed point on a PE pipeline, as a pull-out fuse, installation aid or fixing to pipe supports

- Strength per fixed point up to 40 kN

- Multiple applications possible around the pipe circumference

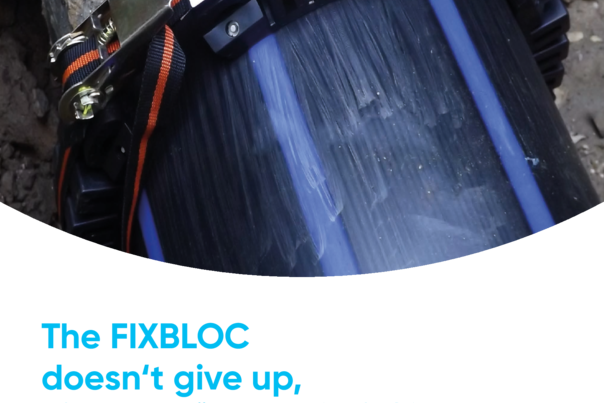

- Processing is carried out with commercially available tensioning straps with a belt width of 50 mm, which are securely guided by two straps (easily removable)

- Minimum length approx. 3.5 x d pipe (longer for multiple applications)

- If the belt around the pipe circumference is not accessible, the clamping device FIXBLOC FWFB (Order No. 613380), e.g. in the case of a PE liner, which must be anchored relative to a shaft wall.

PE 100

Maximum shear load per FIXBLOC: 40 kN

| Reference | d1 | BX | PU | h1 | B | Weight [kg] |

|---|---|---|---|---|---|---|

| 680600 | 160 - 1600 | 15 | 750 | 45 | 60 | 0,320 |

Sewage pipe systems are high-value assets of a value which has to be maintained for a long time. Increasing demands on the public sewage system require materials which meet these criteria. HDPE sewage pipes have been fused for many years with the FRIAFIT HDPE sewage system tightly, frictionlocked and root-proof.

Areas of Application

The FRIAFIT FIXBLOC can be used anywhere, where high levels of axial push-pull forces must be absorbed. For example, for pipe reconstructions, when creating fixed points and fixings.

Thanks to its compact construction, exposed heating coils, which ensure optimum heat transfer and the large fusion zone, high levels of push-pull forces of up to 40 kN per FIXBLOC can be absorbed without a problem. When using several FIXBLOCs on the pipe, high levels of forces can also be absorbed.

Assembly Instructions

The assembly of the FRIAFIT FIXBLOC is simple and rapid using a strap or - where the pipe circumference is not accessible - using the FRIATOOLS FIXBLOC FWFB clamping unit.

With strap assembly the FIXBLOC is fitted on the pipe with a standard strap.

When assembling using the FRIATOOLS FIXBLOC FWFB clamping unit, the FIXBLOC can also be clamped from the cut edge of the pipe and be welded. This is particularly useful if the pipe circumference is not accessible, e.g. with a PE liner in a channel, which must be anchored against the shaft wall.

The fusion process is carried out using standard fusion equipment, e.g. using our FRIAMAT.

Good reasons for using the FRIAFIT FIXBLOC

- Strength for each fixed point up to 40 kN

- Multiple applications around the pipe circumference are possible

- Simple processing using standard straps or using the FIXBLOC FWFB clamping unit

get_app

get_app

get_app

get_app