Gasket EPDM, DIN-EN 681-1 / KTW / UBA / DVGW-W270PFA/PN water, maximum = 16 bar

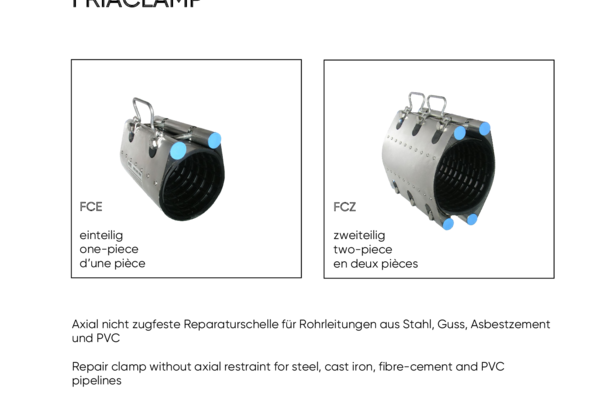

Two-piece repair clamp for sealing damaged gas and water pipes made of different materials (steel, cast iron, ductile iron, asbestos cement, PVC).

- Special gasket design for a secure sealing of tapping holes, cracks and corrosion damage

- Body, closure, bolts and nuts made of stainless steel

- Gasket material EPDM or NBR

Gasket EPDM, DIN-EN 681-1 / KTW / UBA / DVGW-W270

PFA/PN water, maximum = 16 bar

| Reference | d | PN | BX | PU | SW | Weight [kg] |

|---|---|---|---|---|---|---|

| 392-088-200 | 88-110 | 16 | 6 | 192 | 17 | 2,620 |

| 392-088-300 | 88-110 | 16 | 6 | 144 | 17 | 5,560 |

| 392-088-400 | 88-110 | 16 | 6 | 96 | 17 | 7,490 |

| 392-100-200 | 100-120 | 16 | 4 | 192 | 17 | 2,710 |

| 392-100-300 | 100-120 | 16 | 4 | 144 | 17 | 5,740 |

| 392-100-400 | 100-120 | 16 | 4 | 96 | 17 | 7,730 |

| 392-108-200 | 108-128 | 16 | 4 | 128 | 17 | 2,740 |

| 392-108-300 | 108-128 | 16 | 4 | 96 | 17 | 1,780 |

| 392-108-400 | 108-128 | 16 | 4 | 64 | 17 | 5,460 |

| 392-114-200 | 114-134 | 16 | 4 | 128 | 17 | 3,830 |

| 392-114-300 | 114-134 | 16 | 4 | 96 | 17 | 4,270 |

| 392-114-400 | 114-134 | 16 | 4 | 64 | 17 | 8,040 |

| 392-120-200 | 120-140 | 16 | 4 | 128 | 17 | 2,970 |

| 392-120-300 | 120-140 | 16 | 4 | 96 | 17 | 6,040 |

| 392-120-400 | 120-140 | 16 | 4 | 64 | 17 | 8,120 |

| 392-130-200 | 130-150 | 16 | 3 | 64 | 19 | 3,510 |

| 392-130-300 | 130-150 | 16 | 3 | 48 | 19 | 5,350 |

| 392-130-400 | 130-150 | 16 | 3 | 16 | 19 | 1,780 |

| 392-140-200 | 140-160 | 16 | 3 | 64 | 19 | 3,610 |

| 392-140-300 | 140-160 | 16 | 3 | 48 | 19 | 6,260 |

| 392-140-400 | 140-160 | 16 | 3 | 16 | 19 | 8,410 |

| 392-159-200 | 159-180 | 16 | 2 | 64 | 19 | 3,740 |

| 392-159-300 | 159-180 | 16 | 2 | 48 | 19 | 6,520 |

| 392-159-400 | 159-180 | 16 | 2 | 16 | 19 | 8,760 |

| 392-168-200 | 168-189 | 16 | 2 | 64 | 19 | 4,260 |

| 392-168-300 | 168-189 | 16 | 2 | 48 | 19 | 6,620 |

| 392-168-400 | 168-189 | 16 | 2 | 16 | 19 | 8,890 |

| 392-190-200 | 190-210 | 16 | 2 | 64 | 19 | 5,900 |

| 392-190-300 | 190-210 | 16 | 2 | 48 | 19 | 6,860 |

| 392-190-400 | 190-210 | 16 | 2 | 16 | 19 | 9,210 |

| 392-210-200 | 210-230 | 10 | 1 | 32 | 19 | 6,600 |

| 392-210-300 | 210-230 | 10 | 1 | 24 | 19 | 6,810 |

| 392-210-400 | 210-230 | 10 | 1 | 16 | 19 | 9,930 |

| 392-218-200 | 218-238 | 10 | 1 | 32 | 19 | 4,590 |

| 392-218-300 | 218-238 | 10 | 1 | 24 | 19 | 6,970 |

| 392-218-400 | 218-238 | 10 | 1 | 16 | 19 | 10,060 |

| 392-240-200 | 240-260 | 10 | 1 | 32 | 19 | 7,000 |

| 392-240-300 | 240-260 | 10 | 1 | 24 | 19 | 7,170 |

| 392-240-400 | 240-260 | 10 | 1 | 16 | 19 | 10,420 |

| 392-269-200 | 269-289 | 10 | 1 | 32 | 19 | 7,200 |

| 392-269-300 | 269-289 | 10 | 1 | 24 | 19 | 7,570 |

| 392-269-400 | 269-289 | 10 | 1 | 16 | 19 | 10,890 |

| 392-282-200 | 282-302 | 10 | 1 | 32 | 19 | 5,440 |

| 392-282-300 | 282-302 | 10 | 1 | 24 | 19 | 8,280 |

| 392-282-400 | 282-302 | 10 | 1 | 16 | 19 | 11,110 |

| 392-315-200 | 315-335 | 10 | 1 | 32 | 19 | 5,770 |

| 392-315-300 | 315-335 | 10 | 1 | 24 | 19 | 11,650 |

| 392-315-400 | 315-335 | 10 | 1 | 16 | 19 | 11,650 |

| 392-322-300 | 322-344 | 10 | 1 | 24 | 19 | 8,770 |

| 392-322-400 | 322-344 | 10 | 1 | 16 | 19 | 12,000 |

| 392-337-300 | 337-358 | 6 | 1 | 24 | 19 | 11,650 |

| 392-337-400 | 337-358 | 6 | 1 | 36 | 19 | 11,760 |

| 392-347-300 | 347-367 | 6 | 1 | 36 | 19 | 6,090 |

| 392-347-400 | 347-367 | 6 | 1 | 16 | 19 | 6,090 |

| 392-365-400 | 365-385 | 5 | 1 | 32 | 19 | 12,460 |

| 392-410-400 | 410-430 | 5 | 1 | 24 | 19 | 13,360 |

| 392-420-400 | 420-440 | 5 | 1 | 16 | 19 | 11,650 |

Areas of application

FRIACLAMP repair clamps for secure sealing of damaged pipes made of different materials (steel, cast iron, ductile iron, asbestos cement, PVC). Available from DN 40 to DN 300. Also available in one-piece design.

FRIACLAMP repair clamps can be used with the standard NBR gasket for gas, water and wastewater.

Processing instructions

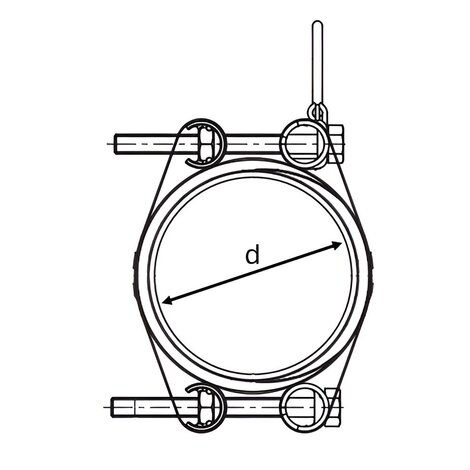

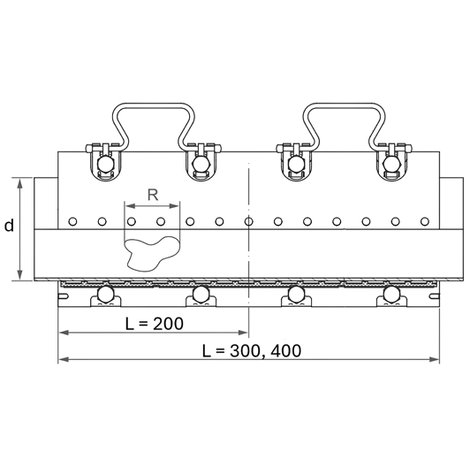

FRIACLAMP can be used to reliably seal damaged pipes. The installation length of the repair clamp should be selected so that it corresponds at least to the outside diameter of the pipe to be repaired.

The pipe surfaces must be prepared in accordance with the general installation requirements (see FRIACLAMP installation instructions).

* Permissible operating pressure:

Gas: Permitted operating pressure 5 bar (≤ DN 300).

Water: Permitted operating pressure:

≤ DN 200 PN 16

> DN 200 PN 10

> DN 300 on request.

Good reasons for FRIACLAMP

- Quick locking System with Nuts and Bolts in V2A

- No welded parts

- Seal with large unique profile

- Dovetail-shaped sealing webs form sealing lips when pressed against the pipe surface

- Secure sealing even on corroded pipe surfaces

- No sharp edges

- No loose parts when opening the one-piece and two-piece repair clamps enable time-saving installation

- Movable handle ensures easy installation with minimum installation space requirements

- Optimized locking mechanism ensures defined pretensioning of each bolt

- Assembly possible with standard tools

get_app

get_app

get_app

get_app