Tapping tee RED SNAP, SDR 11

Tapping tee DAA SDR 11

- Gas, water and H2

- Working pressure: MOP (gas) 10 bar, PFA (water) 16 bar

- Material: PE 100

- Quick release mechanism (RED SNAP):

- Simple and error-free assembly

- Increased quality and safety

- Save 50% of installation time

- Integrated drill with upper and lower inner stop

- Sealing plug with internal sealing O-ring

- Safety technology

- DVGW test mark: DV-6611CS0007

Note:

As a precautionary measure, we recommend additionally using a DK cap for all new DAA installations.

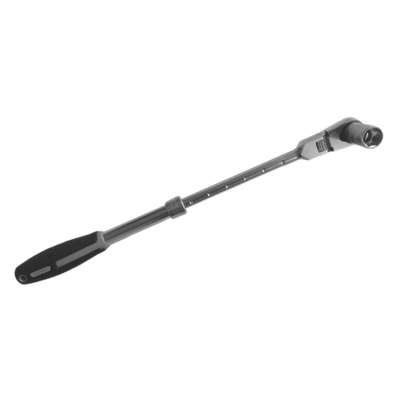

The actuating key FWSS SW 17 (Order no. 613246) must be used for all dimensions.

All outlets (d2) with nominal widths 40 and 50 are always solutions with a reducing sleeve MR.

Special application pressure test:

A pressure test adapter (order no. 613597) is available for the pressure tapping tee.

Areas of Application

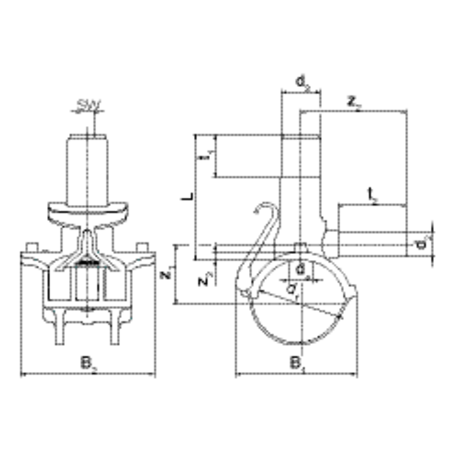

The FRIALEN Pressure Tapping Tees DAA are used as branch fittings and can be fused to mains that are unpressurised or under operating pressure.

Assembly Instructions

The fusion of FRIALEN Pressure Tapping Tee DAA to the PE-HD main and the service pipe takes place by FRIALEN fusing - leakproof and longitudinally strong.

The pipe, saddle and the outlet spigot are prepared (oxide layer removed/cleaned) in accordance with the general installation instructions (see “Assembly instructions” for FRIALEN Safety Fittings for house connections and distribution pipes up to d 225).

Thanks to its innovative and patented clamping mechanism, the FRIALEN Pressure Tapping Tee DAA can also be installed without any tool quickly and reliably on the HD-PE main when it exhibits ovality or has expanded under operating pressure.

Good reasons for using the FRIALEN Pressure Tapping Tees DAA:

- Compact design

- Simple and reliable assembly without any tool thanks to the patented fast clamping lever

- The flexible saddle compensates pipe tolerances and always provides optimal, uniform buildup of melt pressure during fusion

- Assembly without special tools

- The Pressure Tapping Tee is one unit with captive parts

- Only one 17 mm wrench size for tapping and installing the plug

- Chipless tapping

- Leak-free tapping under operating pressure

- Low torque needed for tapping

- Punched-out pipe piece fits securely in the drill

- Stable thread as guidance for the driller during tapping process even at large pipe wall thicknesses and low temperatures

- Solid upper and lower stop of driller, with integrated torque limiter

- Extra wide fusion zone

- After tapping, stack can be fused non-accessible with FRIALEN cap K

- Outlet spigot length measured for two fusion operations

- Additional barcode for traceability (traceability coding)

- Both barcodes exposed on fast clamping lever for easy scanning with readerwand or barcode scanner

get_app

get_app

get_app

get_app