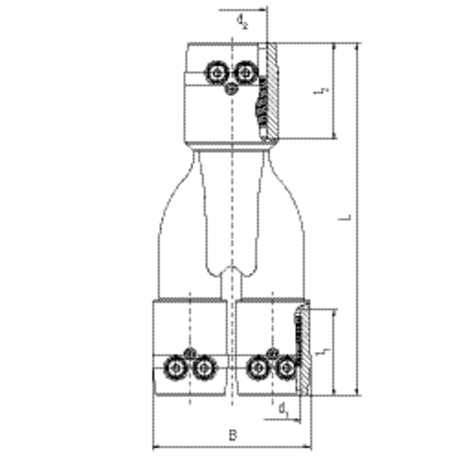

Y-piece, SDR 11

Y-piece Y SDR 11

- Gas and water

- Working pressure: MOP (gas) 10 bar, PFA (water) 16 bar

- Material: PE 100

- Safety technology

- DVGW test mark: DV-8601AU2248

Area of application

The FRIALEN Y-pieces are used for the connection of FRIALEN borehole heat exchanger pipes to be able to operate two or more circuits via a shut-off element or to quickly and efficiently create a direct connection to the heat pump. FRIALEN Y-pieces have a smooth, hydraulically optimised internal contour for optimal flow conditions.

Assembly instructions

The connection of the pipes with FRIALEN Y-pieces made by FRIALEN electrofusion is leak-proof and longitudinally strong.

The PE spigot end of the YS-pieces as well as the borehole heat exchangers- and connection pipes, made of PE 100 or PE 100 plus Geo CR respectively PE 100-RC, get prepared (removing oxide layer/cleaning), according to the general assembly instructions (see “Assembly Instructions” for “FRIALEN-Safety Fittings for house connections and distribution pipes up to d 225”) and can be used for example with a FRIALEN elbow 90°.

Many good reasons for using the FRIALEN Y-pieces:

- 8 mm coupler extension of the Y-piece for more safety when installing coiled pipe because of long guiding- and holding zones

- less space required thanks to compact design

- reduces installation time thanks to integrated fusion couplers giving simultaneously processing safety

- leak-proof, longitudinally strong connection

- exposed, fixed heating coil for direct heat transfer to the pipe

- maximum stability through great wall thickness

- fusion indicators for visual fusion control

- barcode for fully automatic fusion with HDPE pipes from SDR stages 11 to 17.6, taking into consideration the ambient temperature (temperature compensation)

- flexible use enabled due the variation of either Y-piece (3 x coupler) or YS-piece (2 x coupler,1 x spigot end)

- additional barcode for tracing back the component part (Traceability-Coding)

- durable batch marking

- individual foil wrap to prevent dirtying at building site

- touch proof electric contacts

- small annular gap for build-up of optimum joining pressure in the fusion zone

get_app

get_app

get_app

get_app