Reducer, SDR 11

Reducer MR NXT SDR 11

- Gas, water and H2

- Working pressure: MOP (gas) 10 bar, PFA (water) 16 bar

- Material: PE 100 RC

- Safety technology

- Large insertion depth for good pipe routing (no holding devices required)

- DVGW test mark: DV-8601AU2248, DV-8606AU2249, DV-8611AU2250 and DW-8610CN04200

Note:

The availability of the articles must be requested individually for specific markets or countries, as these countries will be switched one by one in 2025/2026.

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water) / 10 bar (gas)

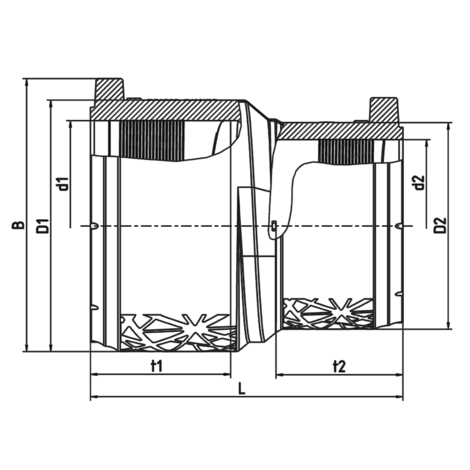

| Reference | d1 | d2 | t1 | t2 | B | d2 | Weight [kg] |

|---|---|---|---|---|---|---|---|

| 617247 | 32 | 20 | 43 | 40 | 59 | 29 | 0,056 |

| 617248 | 32 | 25 | 43 | 40 | 59 | 33 | 0,061 |

| 617249 | 40 | 32 | 48 | 43 | 67,5 | 40,5 | 0,079 |

| 617250 | 50 | 32 | 53 | 43 | 78,5 | 40,5 | 0,102 |

| 617251 | 50 | 40 | 53 | 48 | 78,5 | 49,5 | 0,110 |

| 617252 | 63 | 32 | 52,5 | 43 | 92,5 | 40,5 | 0,144 |

| 617253 | 63 | 40 | 52,5 | 48 | 92,5 | 49,5 | 0,152 |

| 617254 | 63 | 50 | 52,5 | 54 | 92,5 | 61,5 | 0,165 |

| 617255 | 90 | 63 | 71 | 58,5 | 122,5 | 77 | 0,369 |

| 617256 | 90 | 75 | 71 | 64 | 122,5 | 91 | 0,404 |

| 617257 | 110 | 63 | 74 | 59 | 144 | 77 | 0,525 |

| 617258 | 110 | 90 | 74 | 67 | 144 | 109 | 0,582 |

| 617259 | 125 | 90 | 80 | 70 | 160,5 | 132,5 | 0,743 |

| 617260 | 125 | 110 | 80 | 67 | 160,5 | 109 | 0,810 |

| 617261 | 160 | 110 | 95 | 70 | 199 | 132,5 | 1,360 |

Areas of Application

The FRIALEN Electrofusion Reducer MR NXT SDR11 is applied for immediate pipe reduction within the pipe system.

Assembly Instructions

The pipe ends are joined to the FRIALEN Electrofusion Reducers MR NXT SDR11 by electrofusion welding – tight and longitudinally force-fit.

The pipe ends are prepared according to the general installation instructions (see “Assembly Instructions” for “FRIALEN-Safety Fittings).

This involves removing the oxide layer of the pipe end and cleaning of pipe surface.

For removal of the oxide layer, FWSG scraper tools are available which facilitate a uniform swarf removal and a reproducible quality of the fusion area preparation.

Good reasons for using the FRIALEN-Reducer MR NXT SDR11:

- Large coupler depth for ease of pipe guiding (no holding clamps required)

- Maximized fusion zones

- Safety Fittting Design

- 25% lower CO2-Footprint

- Cold zones at the front side and in the middle of the coupler

- Exposed heating coil for direct heat transmission in the fusion zone

- Lowest energy consumption and variable voltage

- Optimised tolerances for “perfect fit” for easy installation

- Touch proof electric contacts

- Fusion indicators for visual fusion control

- Angle and insertion depth markings for quick and safe installation

- Durable batch marking

- Individually wrapped for dirt protection

- 2D barcode for tracing back the fitting (Traceability-Coding).