Axial restraint pipe coupling

STRAUB-GRIP

STRAUB-GRIP Rohrkupplungen sind axial zugfeste Rohrverbindungen für alle metallischen Rohre und starren Kunststoffrohre.

Durch die universelle Verbindungsösung bieten sich unzählige Anwendungsmöglichkeiten auf nahezu allen Rohrsystemen an. Die Installation erfolgt auf glattendigen Rohren, ohne jegliche Rohrendenbearbeitung.

Die kompakte Bauweise erlaubt Leitungsführungen auf engstem Raum. Unerwartete Nebenspannungen, sowie sich bauseits ergebende Ungenauigkeiten bei der Rohrführung, werden aufgrund der flexiblen Bauweise von den Kupplungen aufgenommen. Dies erlaubt eine einfache und schnelle Installation, was spürbare Kostenersparnisse zur Folge hat.

GRIP ø 21.3 - 48.3 mm

| adMm | Clamping range [mm] | PN industry [bar] | PN shipbuilding [bar] | B [mm] | DV [mm] | C (mm) | X [mm] | R without strip insert [mm] | R with strip insert [mm] | Torque rate [Nm] | Allen head [mm] | Thread metric |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 21.3 | 21.0 - 21.6 | 36 | 16 | 46.5 / 75 | 43 | 18 | 56 | 5 | 5 - 10 | 10 | 5 | 6 |

| 25 | 24.5 - 25.5 | 64 | 16 | 46.5 / 75 | 41 | 18 | 53 | 5 | 5 - 10 | 10 | 6 | 8 |

| 26.9 | 26.4 - 27.4 | 58 | 16 | 46.5 / 75 | 44 | 18 | 56 | 5 | 5 - 10 | 10 | 6 | 8 |

| 28 | 27.5 - 28.5 | 50 | 16 | 46.5 / 75 | 45 | 18 | 57 | 5 | 5 - 10 | 10 | 6 | 8 |

| 30 | 29.5 - 30.5 | 42 | 16 | 46.5 / 75 | 47 | 18 | 60 | 5 | 5 - 10 | 10 | 6 | 8 |

| 33.7 | 33.2 - 34.2 | 39 | 16 | 46.5 / 75 | 51 | 18 | 65 | 5 | 5 - 10 | 10 | 6 | 8 |

| 35 | 34.5 - 35.5 | 37 | 16 | 46.5 / 75 | 52 | 18 | 66 | 5 | 5 - 10 | 12 | 6 | 8 |

| 38 | 37.5 - 38.5 | 36 | 16 | 46.5 / 75 | 55 | 18 | 69 | 5 | 5 - 10 | 12 | 6 | 8 |

| 40 | 39.5 - 40.5 | 35 | 16 | 46.5 / 75 | 57 | 18 | 71 | 5 | 5 - 10 | 12 | 6 | 8 |

| 42.4 | 41.9 - 42.9 | 33 | 16 | 46.5 / 75 | 60 | 18 | 74 | 5 | 5 - 10 | 12 | 6 | 8 |

| 44.5 | 44.0 - 45.0 | 30 | 16 | 46.5 / 75 | 62 | 18 | 76 | 5 | 5 - 10 | 12 | 6 | 8 |

| 48.3 | 47.8 - 48.8 | 28 | 16 | 46.5 / 75 | 65 | 18 | 81 | 5 | 5 - 10 | 12 | 6 | 8 |

Remarks:

- Follow fitting instructions

- According to DIN 861 128

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- The pressure values are valid on radial rigid carbon steel pipes under static loads

- Strip inserts are optional accessories

- Additional sealing sleeves and temperature ranges on request

- Follow fitting instructions

- According to DIN 861 128

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- The pressure values are valid on radial rigid carbon steel pipes under static loads

- Strip inserts are optional accessories

- Additional sealing sleeves and temperature ranges on request

GRIP ø 54.0 - 168.3 mm

| adMm | Clamping range [mm] | PN industry [bar] | PN shipbuilding [bar] | B [mm] | DV [mm] | C (mm) | X [mm] | R without strip insert [mm] | R with strip insert [mm] | Torque rate [Nm] | Allen head [mm] | Thread metric |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 54 | 53.5 - 54.5 | 24 | 16 | 65 | 71 | 24 | 87 | 5 | 5 - 15 | 15 | 6 | 8 |

| 57 | 56.4 - 57.6 | 23 | 16 | 65 | 74 | 24 | 90 | 5 | 5 - 15 | 15 | 6 | 8 |

| 60.3 | 59.7 - 60.9 | 23 | 16 | 65 | 77 | 24 | 93 | 5 | 5 - 15 | 15 | 6 | 8 |

| 63 | 62.4 - 63.6 | 23 | 16 | 65 | 80 | 24 | 96 | 5 | 5 - 15 | 15 | 6 | 8 |

| 66.6 | 64.9 - 67.3 | 22 | 16 | 65 | 84 | 24 | 100 | 5 | 5 - 15 | 15 | 6 | 8 |

| 70 | 68.9 - 70.7 | 22 | 16 | 65 | 87 | 24 | 104 | 5 | 5 - 15 | 15 | 6 | 8 |

| 73 | 72.3 - 73.7 | 21 | 16 | 65 | 90 | 24 | 107 | 5 | 5 - 15 | 15 | 6 | 8 |

| 76.1 | 75.3 - 76.9 | 35 | 16 | 100 | 100 | 40 | 122 | 5 - 10 | 5 - 25 | 20 | 8 | 10 |

| 79.5 | 78.7 - 80.3 | 32 | 16 | 100 | 103 | 40 | 125 | 5 - 10 | 5 - 25 | 20 | 8 | 10 |

| 84 | 83.2 - 84.8 | 29 | 16 | 100 | 107 | 40 | 130 | 5 - 10 | 5 - 25 | 20 | 8 | 10 |

| 88.9 | 88.0 - 89.8 | 26 | 16 | 100 | 112 | 40 | 134 | 5 - 10 | 5 - 25 | 20 | 8 | 10 |

| 95 | 94.0 - 96.0 | 24 | 16 | 100 | 117 | 40 | 139 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 98 | 97.0 - 99.0 | 24 | 16 | 100 | 121 | 40 | 143 | 5 - 10 | 5 - 25 | 35 | 8 | 10 |

| 100.6 | 99.6 - 101.6 | 23 | 16 | 100 | 124 | 40 | 146 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 101.6 | 100.6 - 102.6 | 23 | 16 | 100 | 125 | 40 | 146 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 104 | 103.0 - 105.0 | 23 | 16 | 100 | 127 | 40 | 148 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 104.8 | 103.8 - 105.8 | 23 | 16 | 100 | 128 | 40 | 150 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 108 | 106.9 - 109.1 | 22 | 16 | 100 | 132 | 40 | 154 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 114.3 | 113.2 - 115.4 | 22 | 16 | 100 | 138 | 40 | 160 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 118 | 116.9 - 119.1 | 22 | 16 | 100 | 142 | 40 | 166 | 5 - 10 | 5 - 25 | 35 | 8 | 10 |

| 122 | 120.6 - 123.4 | 21 | 16 | 115 | 149 | 53 | 170 | 5 - 10 | 5 - 30 | 35 | 10 | 12 |

| 125 | 123.7 - 126.3 | 21 | 16 | 115 | 152 | 53 | 174 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 127 | 125.7 - 128.3 | 21 | 16 | 115 | 154 | 53 | 176 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 129 | 127.7 - 130.3 | 21 | 16 | 115 | 156 | 53 | 178 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 130.2 | 128.9 - 131.5 | 21 | 16 | 115 | 157 | 53 | 179 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 133 | 131.7 - 134.3 | 21 | 16 | 115 | 160 | 53 | 182 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 139.7 | 138.3 - 141.1 | 20 | 16 | 115 | 166 | 53 | 189 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 141.3 | 139.9 - 142.7 | 20 | 16 | 115 | 168 | 53 | 190 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 144 | 142.6 - 145.4 | 20 | 16 | 115 | 171 | 53 | 183 | 5 - 10 | 5 - 30 | 60 | 10 | 12 |

| 154 | 152.5 - 155.5 | 18 | 16 | 115 | 181 | 53 | 203 | 5 - 10 | 5 - 30 | 50 | 10 | 12 |

| 159 | 157.4 - 160.6 | 18 | 16 | 115 | 186 | 53 | 208 | 5 - 10 | 5 - 30 | 50 | 10 | 12 |

| 165 | 163.4 - 166.6 | 16 | 16 | 115 | 192 | 53 | 214 | 5 - 10 | 5 - 30 | 50 | 10 | 12 |

| 168.3 | 166.6 - 170.0 | 16 | 16 | 115 | 195 | 53 | 217 | 5 - 10 | 5 - 30 | 50 | 10 | 12 |

Remarks:

- Follow fitting instructions

- According to DIN 861 128

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- The pressure values are valid on radial rigid carbon steel pipes under static loads

- Strip inserts are optional accessories

- Additional sealing sleeves and temperature ranges on request

- Follow fitting instructions

- According to DIN 861 128

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- The pressure values are valid on radial rigid carbon steel pipes under static loads

- Strip inserts are optional accessories

- Additional sealing sleeves and temperature ranges on request

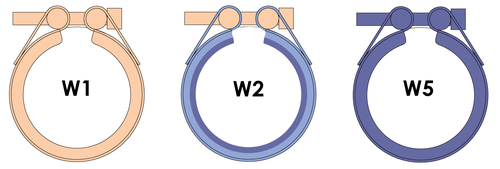

STRAUB pipe couplings are made of the same or different materials depending on the diameter and size. The following overview shows the details. If you have any questions, please contact our application engineering department.

GRIP ø 21.3 - 48.3 mm

| Components | W1 | W2 | W5 |

|---|---|---|---|

| - | - | AISI 316 L / LDX 2101 | |

| - | - | A4 - 80 | |

| - | - | AISI 316 L or similar | |

| - | - | AISI 301 | |

| - | - | AISI 316 L / PVDF |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|

GRIP ø 54.0 - 168.3 mm

| Components | W1 | W2 | W5 |

|---|---|---|---|

| - | - | AISI 316 L / LDX 2101 | |

| - | - | A4 - 80 | |

| - | - | AISI 316 L or similar | |

| - | - | AISI 301 | |

| - | - | AISI 316 L / PVDF |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|