Fire protection system

STRAUB-GRIP-FIRE-FENCE

The original STRAUB fire protection system for applications where fire protection is required.

The STRAUB FIRE-FENCE is the optimum solution for fire extinguishing equipment as well as for various systems with increased fire protection requirements such as in civil engineering (tunnels), for shipyards for seagoing vessels with various requirements and other applications.

The STRAUB-FIRE-FENCE system is based on the standard types of the STRAUB-GRIP and STRAUB-FLEX series. In addition, an intumescent plastic is firmly bonded to the outside of the casing. In the event of fire, this swells and encloses the pipe coupling in a protective manner - while retaining full functionality.

GRIP-FIRE-FENCE ø 25.0 - 48.3 mm

| adMm | Clamping range [mm] | PN industry [bar] | PN shipbuilding [bar] | B [mm] | DV [mm] | C (mm) | X [mm] | R without strip insert [mm] | R with strip insert [mm] | Torque rate [Nm] | Allen head [mm] | Thread metric |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 24.5 - 25.5 | 64 | 16 | 54 / 78 | 51 | 18 | 58 | 5 | 5 - 10 | 10 | 6 | 8 |

| 26.9 | 26.4 - 27.4 | 58 | 16 | 54 / 78 | 54 | 18 | 61 | 5 | 5 - 10 | 10 | 6 | 8 |

| 28 | 27.5 - 28.5 | 50 | 16 | 54 / 78 | 55 | 18 | 62 | 5 | 5 - 10 | 10 | 6 | 8 |

| 30 | 29.5 - 30.5 | 42 | 16 | 54 / 78 | 57 | 18 | 65 | 5 | 5 - 10 | 10 | 6 | 8 |

| 33.7 | 33.2 - 34.2 | 39 | 16 | 54 / 78 | 61 | 18 | 70 | 5 | 5 - 10 | 10 | 6 | 8 |

| 35 | 34.5 - 35.5 | 37 | 16 | 54 / 78 | 62 | 18 | 71 | 5 | 5 - 10 | 12 | 6 | 8 |

| 38 | 37.5 - 38.5 | 36 | 16 | 54 / 78 | 65 | 18 | 74 | 5 | 5 - 10 | 12 | 6 | 8 |

| 40 | 39.5 - 40.5 | 35 | 16 | 54 / 78 | 67 | 18 | 76 | 5 | 5 - 10 | 12 | 6 | 8 |

| 42.4 | 41.9 - 42.9 | 33 | 16 | 54 / 78 | 70 | 18 | 79 | 5 | 5 - 10 | 12 | 6 | 8 |

| 44.5 | 44.0 - 45.0 | 30 | 16 | 54 / 78 | 72 | 18 | 81 | 5 | 5 - 10 | 12 | 6 | 8 |

| 48.3 | 47.8 - 48.8 | 28 | 16 | 54 / 78 | 75 | 18 | 86 | 5 | 5 - 10 | 12 | 6 | 8 |

Remarks:

- Follow fitting instructions

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- The pressure values are valid on radial rigid carbon steel pipes under static loads

- Additional sealing sleeves and temperature ranges on request

- Follow fitting instructions

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- The pressure values are valid on radial rigid carbon steel pipes under static loads

- Additional sealing sleeves and temperature ranges on request

GRIP-FIRE-FENCE ø 54.0 - 168.3 mm

| adMm | Clamping range [mm] | PN industry [bar] | PN shipbuilding [bar] | B [mm] | DV [mm] | C (mm) | X [mm] | R without strip insert [mm] | R with strip insert [mm] | Torque rate [Nm] | Allen head [mm] | Thread metric |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 54 | 53.5 - 54.5 | 24 | 16 | 71 | 81 | 24 | 92 | 5 | 5 - 15 | 15 | 6 | 8 |

| 57 | 56.4 - 57.6 | 23 | 16 | 71 | 84 | 24 | 95 | 5 | 5 - 15 | 15 | 6 | 8 |

| 60.3 | 59.7 - 60.9 | 23 | 16 | 71 | 87 | 24 | 98 | 5 | 5 - 15 | 15 | 6 | 8 |

| 63 | 62.4 - 63.6 | 23 | 16 | 71 | 90 | 24 | 101 | 5 | 5 - 15 | 15 | 6 | 8 |

| 66.6 | 64.9 - 67.3 | 22 | 16 | 71 | 94 | 24 | 105 | 5 | 5 - 15 | 15 | 6 | 8 |

| 70 | 68.9 - 70.7 | 22 | 16 | 71 | 97 | 24 | 109 | 5 | 5 - 15 | 15 | 6 | 8 |

| 73 | 72.3 - 73.7 | 21 | 16 | 71 | 100 | 24 | 112 | 5 | 5 - 15 | 15 | 6 | 8 |

| 76.1 | 75.3 - 76.9 | 35 | 16 | 106 | 110 | 40 | 127 | 5 - 10 | 5 - 25 | 20 | 8 | 10 |

| 79.5 | 78.7 - 80.3 | 32 | 16 | 106 | 113 | 40 | 130 | 5 - 10 | 5 - 25 | 20 | 8 | 10 |

| 84 | 83.2 - 84.8 | 29 | 16 | 106 | 117 | 40 | 135 | 5 - 10 | 5 - 25 | 20 | 8 | 10 |

| 88.9 | 88.0 - 89.8 | 26 | 16 | 106 | 122 | 40 | 139 | 5 - 10 | 5 - 25 | 20 | 8 | 10 |

| 95 | 94.0 - 96.0 | 24 | 16 | 106 | 127 | 40 | 144 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 98 | 97.0 - 99.0 | 24 | 16 | 106 | 131 | 40 | 148 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 100.6 | 99.6 - 101.6 | 23 | 16 | 106 | 134 | 40 | 151 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 101.6 | 100.6 - 102.6 | 23 | 16 | 106 | 135 | 40 | 151 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 104 | 103.0 - 105.0 | 23 | 16 | 106 | 137 | 40 | 153 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 104.8 | 103.8 - 105.8 | 23 | 16 | 106 | 138 | 40 | 155 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 108 | 106.9 - 109.1 | 22 | 16 | 106 | 142 | 40 | 159 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 114.3 | 113.2 - 115.4 | 22 | 16 | 106 | 148 | 40 | 165 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 118 | 116.9 - 119.1 | 22 | 16 | 106 | 152 | 40 | 171 | 5 - 10 | 5 - 25 | 25 | 8 | 10 |

| 125 | 123.7 - 126.3 | 21 | 16 | 121 | 162 | 53 | 179 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 127 | 125.7 - 128.3 | 21 | 16 | 121 | 164 | 53 | 181 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 129 | 127.7 - 130.3 | 21 | 16 | 121 | 166 | 53 | 183 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 130.2 | 128.9 - 131.5 | 21 | 16 | 121 | 167 | 53 | 184 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 133 | 131.7 - 134.3 | 21 | 16 | 121 | 170 | 53 | 187 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 139.7 | 138.3 - 141.1 | 20 | 16 | 121 | 176 | 53 | 194 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 141.3 | 139.9 - 142.7 | 20 | 16 | 121 | 178 | 53 | 195 | 5 - 10 | 5 - 30 | 40 | 10 | 12 |

| 144 | 142.6 - 145.4 | 20 | 16 | 121 | 181 | 53 | 188 | 5 - 10 | 5 - 30 | 50 | 10 | 12 |

| 154 | 152.5 - 155.5 | 18 | 16 | 121 | 191 | 53 | 208 | 5 - 10 | 5 - 30 | 50 | 10 | 12 |

| 159 | 157.4 - 160.6 | 18 | 16 | 121 | 196 | 53 | 213 | 5 - 10 | 5 - 30 | 50 | 10 | 12 |

| 165 | 163.4 - 166.6 | 16 | 16 | 121 | 202 | 53 | 219 | 5 - 10 | 5 - 30 | 50 | 10 | 12 |

| 168.3 | 166.6 - 170.0 | 16 | 16 | 121 | 205 | 53 | 222 | 5 - 10 | 5 - 30 | 50 | 10 | 12 |

Remarks:

- Follow fitting instructions

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- The pressure values are valid on radial rigid carbon steel pipes under static loads

- Additional sealing sleeves and temperature ranges on request

- Follow fitting instructions

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- The pressure values are valid on radial rigid carbon steel pipes under static loads

- Additional sealing sleeves and temperature ranges on request

STRAUB pipe couplings are made of the same or different materials depending on the diameter and size. The following overview shows the details. If you have any questions, please contact our application technology department.

GRIP-FIRE-FENCE ø 25.0 - 48.3 mm

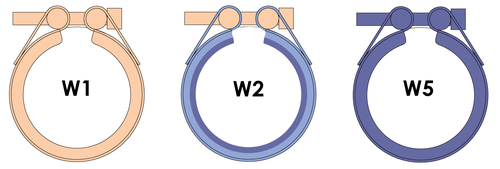

| Components | W1 | W2 | W5 |

|---|---|---|---|

| - | AISI 316 L or similar | ||

| - | - | A4 - 80 | |

| - | - | AISI 316 L or similar | |

| - | - | AISI 301 | |

| - | - | AISI 316 L / PVDF |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|

GRIP-FIRE-FENCE ø 54.0 - 168.3 mm

| Components | W1 | W2 | W5 |

|---|---|---|---|

| - | AISI 316 L or similar | ||

| - | - | A4 - 80 | |

| - | - | AISI 316 L or similar | |

| - | - | AISI 301 | |

| - | - | AISI 316 L / PVDF |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|