Non-tension resistant pipe coupling

STRAUB-STEP-FLEX

STRAUB-STEP-FLEX is used if the pipes have different external diameters.

The possible diameter differences of the pipes to be connected can be 10 mm up to max. 30 mm.

Under pressure, STRAUB-STEP-FLEX pipe couplings, due to the diameter differences, are always pushed by internal forces in the direction of the smaller pipe diameter and must therefore be secured against slipping using appropriate measures.

STEP-FLEX 2 ø 219.1 - 812.8 mm

| adMm | OD 2 [mm] | OD 2 max [mm] | PN Industry [bar] 25 | PN Industry [bar] 6 | PN Industry [bar] 10 | PN Industry [bar] 16 | PN Industry [bar] 20 | PN Industry [bar] 2.5 |

|---|---|---|---|---|---|---|---|---|

| 219.1 | 230 | 250 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 |

| 250 | 260 | 280 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 |

| 267 | 277 | 297 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 |

| 273 | 283 | 303 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 |

| 304 | 314 | 334 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 |

| 323.9 | 334 | 354 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 |

| 355.6 | 366 | 386 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 |

| 406.4 | 416 | 436 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 457.2 | 467 | 487 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 508 | 518 | 538 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 558.8 | 569 | 589 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 |

| 609.6 | 620 | 640 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 |

| 711.2 | 721 | 741 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W1 |

| 762 | 772 | 792 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W1 |

| 812.8 | 823 | 843 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | - |

Remarks:

- Follow fitting instructions

- PN = working pressure considering the application loads

- Test pressure = PN x 1.5 (for example industry, water supply etc.)

- Stainless steel strip insert included

- Additional sealing sleeves, pressure and temperature ranges on request

- Follow fitting instructions

- PN = working pressure considering the application loads

- Test pressure = PN x 1.5 (for example industry, water supply etc.)

- Stainless steel strip insert included

- Additional sealing sleeves, pressure and temperature ranges on request

STEP-FLEX 3 ø 914.4 - 2032.0 mm

| adMm | OD 2 [mm] | OD 2 max [mm] | PN Industry [bar] 25 | PN Industry [bar] 6 | PN Industry [bar] 10 | PN Industry [bar] 16 | PN Industry [bar] 20 |

|---|---|---|---|---|---|---|---|

| 914.4 | 924 | 934 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W1 |

| 1016 | 1026 | 1046 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W1 |

| 1117.6 | 1127 | 1147 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | - |

| 1219.2 | 1229 | 1249 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | - |

| 1320.8 | 1331 | 1351 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | - |

| 1422.4 | 1432 | 1452 | W1 | W2 | W5 | W1 | W5 | W1 | W1 | - |

| 1524 | 1534 | 1554 | W1 | W2 | W5 | W1 | W5 | W1 | - | - |

| 1600 | 1610 | 1630 | W1 | W2 | W5 | W1 | W5 | W1 | - | - |

| 1625.4 | 1635 | 1655 | W1 | W2 | W5 | W1 | W5 | W1 | - | - |

| 1727.2 | 1737 | 1757 | W1 | W2 | W5 | W1 | W5 | W1 | - | - |

| 1828.8 | 1839 | 1859 | W1 | W2 | W5 | W1 | W5 | W1 | - | - |

| 1930.4 | 1940 | 1960 | W1 | W2 | W5 | W1 | W5 | W1 | - | - |

| 2032 | 2042 | 2062 | W1 | W2 | W5 | W1 | W5 | W1 | - | - |

Remarks:

- Follow fitting instructions

- PN = working pressure considering the application loads

- Test pressure = PN x 1.5 (for example industry, water supply etc.)

- Stainless steel strip insert included

- Additional sealing sleeves, pressure and temperature ranges on request

- Follow fitting instructions

- PN = working pressure considering the application loads

- Test pressure = PN x 1.5 (for example industry, water supply etc.)

- Stainless steel strip insert included

- Additional sealing sleeves, pressure and temperature ranges on request

STRAUB pipe couplings are made of the same or different materials depending on the diameter and size. The following overview shows the details. If you have any questions, please contact our application technology department.

STEP-FLEX 2 ø 219.1 - 812.8 mm

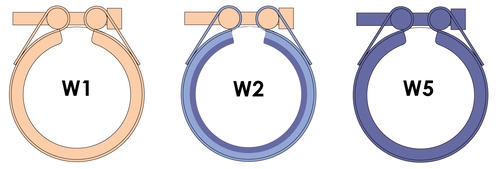

| Components | W1 | W2 | W5 |

|---|---|---|---|

| S355MC, hot-dip galvanised | AISI 316 L or similar | AISI 316 L or similar | |

| AISI 4135 | AISI 4135 | A4 - 80 | |

| AISI 12L14, galvanised | AISI 12L14, galvanised | AISI 316 L or similar | |

| AISI 316 L or similar | AISI 316 L or similar | AISI 316 L or similar |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|

STEP-FLEX 3 ø 914.4 - 2032.0 mm

| Components | W1 | W2 | W5 |

|---|---|---|---|

| S355MC, hot-dip galvanised | AISI 316 L or simiIar | AISI 316 L or similar | |

| AISI 4135 | AISI 4135 | A4 - 80 | |

| AISI 12L14, galvanised | AISI 12L14, galvanised | AISI 316 L or similar | |

| AISI 316 L or similar | AISI 316 L or similar | AISI 316 L or similar |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|