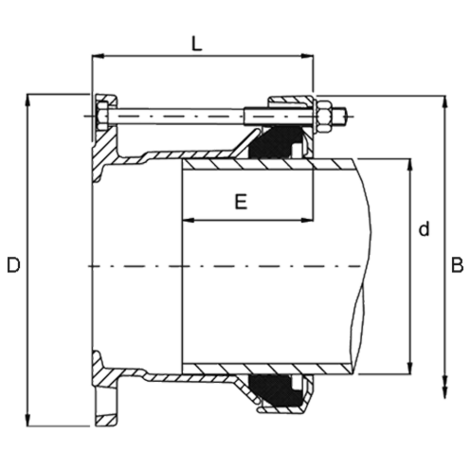

Ultra-Range Flange Adaptor

Flange adapter for connecting pipes made of different materials (steel, cast iron, ductile cast iron, asbestos cement, PVC, PE-HD/PEX).

- Housing and follower ring made of ductile cast iron (EN-GS-450-10)

- Rilsan corrosion protection (min. 250 µm according to GSK)

- Screws and nuts galvanized/sheraplex-coated or made of stainless steel

- Seal material EPDM or NBR

- Diameter tolerance max. 34 mm depending on dimensions

- Pipes can be angled by max. 4 degrees

- Flange connection dimensions in accordance with DIN EN1092, PN 10 and PN 16

- Temperature-Range: -20°C - +30°C

Note:

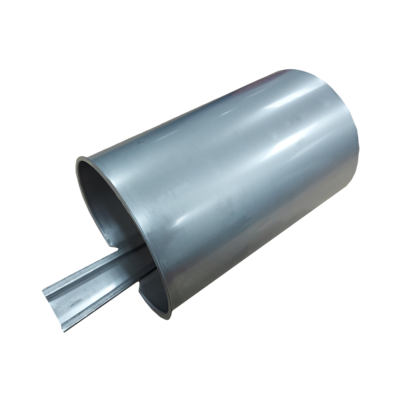

When used on PE-HD/PEX pipes, our SHVA inner support liner is required. Alternatively, we recommend the longitudinally force-locking product FRIAGRIP.

Nuts and bolts galvanized and sheraplex coated Gasket EPDM, DIN-EN 681-1 / KTW / UBA / DVGW-W270

PFA /PN Water: up to DN 300 = 16 bar, larger DN 300 = 10 bar

| Reference | d | DN | Flansch DN | Flansch PN | BX | PU | D | t min | t max | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| UR-14R9-043-05 | 43,5-63,5 | 40/50 | 50 | 10/16 | 4 | 96 | 167 | 80 | 90 | 4,100 |

| UR-14R9-063-06 | 63,0-83,7 | 65 | 65 | 10/16 | 4 | 96 | 185 | 80 | 90 | 4,950 |

| UR-14R9-085-08 | 85,7-107,0 | 80 | 80 | 10/16 | 2 | 60 | 200 | 80 | 110 | 5,850 |

| UR-14R9-107-10 | 107,2-133,2 | 100 | 100 | 10/16 | 2 | 48 | 234 | 85 | 110 | 8,900 |

| UR-14R9-132-12 | 132,2-160,2 | 125 | 125 | 10/16 | 2 | 48 | 268 | 90 | 120 | 10,700 |

| UR-14R9-158-15 | 158,2-192,2 | 150 | 150 | 10/16 | 1 | 18 | 317 | 100 | 125 | 14,700 |

| UR-14R9-192-20 | 192,2-226,9 | 175 | 200 | 10/16 | 1 | 18 | 344 | 100 | 150 | 18,000 |

| UR-14R9-218-20 | 218,1-252,1 | 200 | 200 | 10/16 | 1 | 18 | 374 | 100 | 150 | 20,950 |

| UR-14R9-266-25 | 266,2-300,2 | 250 | 250 | 10/16 | 1 | 4 | 424 | 100 | 180 | 32,200 |

| UR-14R9-315-30 | 315,0-349,0 | 300 | 300 | 10/16 | 1 | 4 | 472 | 100 | 180 | 39,200 |

Nuts and Bolts Stainless steel ,Gasket EPDM, DIN-EN 681-1 / KTW / UBA / DVGW-W270

PFA /PN Water: up to DN 300 = 16 bar, larger DN 300 = 10 bar

| Reference | d | DN | Flansch DN | Flansch PN | BX | PU | D | t min | t max | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| UR-14R9X043-05 | 43,5-63,5 | 40/50 | 50 | 10/16 | 4 | 96 | 167 | 80 | 90 | 4,100 |

| UR-14R9X063-06 | 63,0-83,7 | 65 | 65 | 10/16 | 4 | 96 | 185 | 80 | 90 | 4,800 |

| UR-14R9X085-08 | 85,7-107,0 | 80 | 80 | 10/16 | 2 | 60 | 200 | 80 | 110 | 5,830 |

| UR-14R9X107-10 | 107,2-133,2 | 100 | 100 | 10/16 | 2 | 48 | 234 | 85 | 110 | 9,100 |

| UR-14R9X132-12 | 132,2-160,2 | 125 | 125 | 10/16 | 2 | 48 | 268 | 90 | 120 | 10,500 |

| UR-14R9X158-15 | 158,2-192,2 | 150 | 150 | 10/16 | 1 | 18 | 317 | 100 | 125 | 13,500 |

| UR-14R9X192-20 | 192,2-226,9 | 175 | 200 | 10/16 | 1 | 18 | 344 | 100 | 150 | 17,200 |

| UR-14R9X218-20 | 218,1-252,1 | 200 | 200 | 10/16 | 1 | 18 | 374 | 100 | 150 | 22,400 |

| UR-14R9X266-25 | 266,2-300,2 | 250 | 250 | 10/16 | 1 | 4 | 424 | 100 | 180 | 32,800 |

| UR-14R9X315-30 | 315,0-349,0 | 300 | 300 | 10/16 | 1 | 4 | 472 | 100 | 180 | 39,400 |

Nuts and bolts galvanized and sheraplex coated, Gasket NBR, DIN-EN 682 MOP Gas = 5 bar / other water qualities = 16 bar

| Reference | d | DN | Flansch DN | Flansch PN | BX | PU | D | t min | t max | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| UR-14R2-043-05 | 43,5-63,5 | 40/50 | 50 | 10/16 | 4 | 96 | 167 | 80 | 90 | 4,100 |

| UR-14R2-063-06 | 63,0-83,7 | 65 | 65 | 10/16 | 4 | 96 | 185 | 80 | 90 | 4,950 |

| UR-14R2-085-08 | 85,7-107,0 | 80 | 80 | 10/16 | 2 | 60 | 200 | 80 | 110 | 5,850 |

| UR-14R2-107-10 | 107,2-133,2 | 100 | 100 | 10/16 | 2 | 48 | 234 | 85 | 110 | 8,900 |

| UR-14R2-132-12 | 132,2-160,2 | 125 | 125 | 10/16 | 2 | 48 | 268 | 90 | 120 | 10,700 |

| UR-14R2-158-15 | 158,2-192,2 | 150 | 150 | 10/16 | 1 | 18 | 317 | 100 | 125 | 14,700 |

| UR-14R2-192-20 | 192,2-226,9 | 175 | 200 | 10/16 | 1 | 18 | 344 | 100 | 150 | 18,000 |

| UR-14R2-218-20 | 218,1-252,1 | 200 | 200 | 10/16 | 1 | 18 | 374 | 100 | 150 | 20,950 |

| UR-14R2-266-25 | 266,2-300,2 | 250 | 250 | 10/16 | 1 | 4 | 424 | 100 | 180 | 32,200 |

| UR-14R2-315-30 | 315,0-349,0 | 300 | 300 | 10/16 | 1 | 4 | 472 | 100 | 180 | 39,200 |

Nuts and bolts Stainless Steel, Gasket NBR, DIN-EN 682 MOP Gas = 5 bar / other water qualities = 16 bar

| Reference | d | DN | Flansch DN | Flansch PN | BX | PU | D | t min | t max | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| UR-14R2X043-05 | 43,5-63,5 | 40/50 | 50 | 10/16 | 4 | 96 | 167 | 80 | 90 | 4,100 |

| UR-14R2X063-06 | 63,0-83,7 | 65 | 65 | 10/16 | 4 | 96 | 185 | 80 | 90 | 4,800 |

| UR-14R2X085-08 | 85,7-107,0 | 80 | 80 | 10/16 | 2 | 60 | 200 | 80 | 110 | 5,830 |

| UR-14R2X107-10 | 107,2-133,2 | 100 | 100 | 10/16 | 2 | 48 | 234 | 85 | 110 | 9,100 |

| UR-14R2X132-12 | 132,2-160,2 | 125 | 125 | 10/16 | 2 | 48 | 268 | 90 | 120 | 10,500 |

| UR-14R2X158-15 | 158,2-192,2 | 150 | 150 | 10/16 | 1 | 18 | 317 | 100 | 125 | 13,500 |

| UR-14R2X192-20 | 192,2-226,9 | 175 | 200 | 10/16 | 1 | 18 | 344 | 100 | 150 | 17,200 |

| UR-14R2X218-20 | 218,1-252,1 | 200 | 200 | 10/16 | 1 | 18 | 374 | 100 | 150 | 22,400 |

| UR-14R2X266-25 | 266,2-300,2 | 250 | 250 | 10/16 | 1 | 4 | 424 | 100 | 180 | 32,800 |

| UR-14R2X315-30 | 315,0-349,0 | 300 | 300 | 10/16 | 1 | 4 | 472 | 100 | 180 | 39,400 |

Application areas

Ultra-Range flange adapters and couplings are flexible connectors for pipes made of steel, cast iron, ductile iron, fiber cement, PVC, PE-HD/PEX, available from DN 40 to DN 300.

The clamping ranges up to DN 300 are designed so that a component can be used on all pipe materials of a nominal diameter.

The flange patterns for URFA are generally designed in PN 10 and PN 16 in accordance with EN 1092.

Ultra-Range can be subjected to operating pressures of up to 16 bar for water and up to PN 5 for gas.

Ultra-Range can be used with NBR gaskets for gas, water and waste water, and with EPDM gaskets (DVGW-W270 [11.2007], KTW) in drinking water distribution networks. Screws and nuts correspond to strength class 8.8/8 and are galvanized/sheraplex-coated or made of stainless steel.

Processing instructions

Ultra-Range can be used to make flexible connections between pipes made of the same or different materials.

The pipe ends must be prepared in accordance with the general installation requirements (see FRIAGRIP installation instructions).

The insertion depths tmin./tmax. must be observed.

When using PE-HD/PEX pipes, the FRIAGRIP support sleeve (type FRIATEC Mod. SHVA, see current FRIAGRIP price list) must be used. Alternatively, we recommend the restrained products FRIAGRIP

Good reasons for Ultra-Range

Proven design, body and follower ring made of ductile cast iron GGG40 and coated with RILSAN®

Flanges are generally drilled to PN 10 and PN 16

The components are supplied pre-assembled at the factory, so no conversion or replacement work is required on site

One gasket for the pipe materials steel, cast iron, ductile cast iron, fiber cement, PVC, PE-HD/PEX

Pipes can be angled up to 8° (URK) or 4° (URFA). In the event of pipe fractures, a misalignment can be compensated for by installing two couplings. The couplings act like a joint and keep the pipe stress-free

Simple installation with standard tools

One torque for all pipe materials

It is not necessary to check the tightening torque of the screws several times

The tolerance range of up to 34 mm enables different pipe materials to be connected to one component. Reduced stock levels for suppliers and retailers