UltraGrip Flange Adaptor

Restrained flange adapter for connecting pipes made of different materials (steel, cast iron, ductile iron, asbestos cement, PVC, PE-HD/PEX) in civil engineering.

- Housing and bonnet-ring made of ductile iron (EN-GS-450-10)

- Corrosion protection Rilsan (min. 250 µm according to GSK)

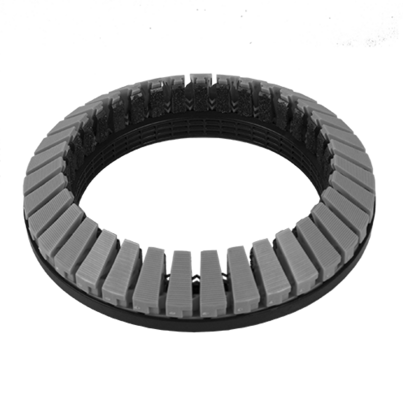

- One gripping system for all pipe materials gripping segment made of acetal, corundum coated

- Sealing material EPDM or NBR

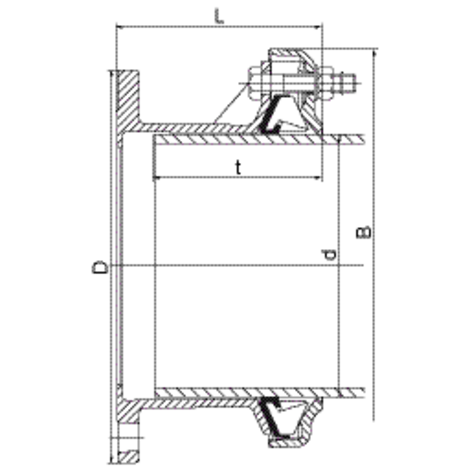

- Diameter range depending on size up to max. 54 mm

- Stainless steel or galvanized screws and nuts

- Angular deflection of 4 degrees

- Flange connection dimensions according to DIN EN1092, PN 10 and PN 16

- Temperature range: -20°C - +30°C

A notice:

When used on PE-HD/PEX pipes, our inner support liner SHVA is required.

When used on AZ pipes, restrained cannot be entirely ensured.

Gasket EPDM, DIN-EN 681-1 / KTW / UBA / DVGW-W270

PFA /PN Water: up to DN 300 = 16 bar, larger DN 300 = 10 bar

| Reference | d | DN | Flansch DN | Flansch PN | BX | PU | D | t min | t max | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| 672000 | 43,5-63,5 | 40 | 40 | 10/16 | 4 | 96 | 150 | 65 | 110 | 4,200 |

| 672001 | 43,5-63,5 | 40 | 50 | 10/16 | 4 | 96 | 165 | 65 | 110 | 4,200 |

| 672002 | 48,0-71,0 | 50 | 50 | 10/16 | 1 | 96 | 165 | 65 | 110 | 5,200 |

| 672003 | 63,0-83,7 | 65 | 65 | 10/16 | 4 | 96 | 185 | 65 | 110 | 5,200 |

| 672005 | 85,7-107,0 | 80 | 80 | 10/16 | 2 | 60 | 200 | 65 | 110 | 6,200 |

| 672007 | 107,2-133,2 | 100 | 100 | 10/16 | 2 | 36 | 220 | 90 | 125 | 10,000 |

| 672009 | 132,2-160,2 | 125 | 125 | 10/16 | 2 | 24 | 252 | 90 | 135 | 11,600 |

| 672011 | 158,2-192,2 | 150 | 150 | 10/16 | 1 | 18 | 285 | 90 | 125 | 14,750 |

| 672013 | 192,2-226,9 | 175 | 200 | 10/16 | 1 | 18 | 340 | 125 | 165 | 25,000 |

| 672015 | 218,1-256,0 | 200 | 200 | 10/16 | 1 | 12 | 340 | 125 | 165 | 22,600 |

| 672017 | 266,2-310,2 | 250 | 250 | 10/16 | 1 | 4 | 400 | 125 | 165 | 38,000 |

| 672019 | 315,0-356,0 | 300 | 300 | 10/16 | 1 | 4 | 470 | 125 | 200 | 42,500 |

| 672021 | 352,2-396,0 | 350 | 350 | 10/16 | 1 | - | 520 | 125 | 200 | 50,000 |

| 672023 | 398,2-442,0 | 400 | 400 | 10/16 | 1 | - | 580 | 125 | 200 | 60,000 |

| 672025 | 448,0-492,0 | 400+ | 400 | 10/16 | 1 | - | 580 | 125 | 200 | 135,000 |

| 672027 | 498,0-552,0 | 500 | 500 | 10/16 | 1 | - | 715 | 140 | 215 | 109,000 |

| 672029 | 558,0-608,0 | 500+ | 500 | 10/16 | 1 | - | 715 | 140 | 215 | 125,000 |

| 672031 | 604,0-648,0 | 600 | 600 | 10/16 | 1 | - | 840 | 195 | 255 | 101,000 |

| 672033 | 676,0-726,0 | 600+ | 600 | 10/16 | 1 | - | 840 | 195 | 255 | 165,000 |

Gasket NBR, DIN-EN 682

MOP Gas: up to DN 400 = 5 bar

Other water qualities PFA /PN: up to DN 300 = 16 bar, larger DN 300 = 10 bar

| Reference | d | DN | Flansch DN | Flansch PN | BX | PU | D | t min | t max | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| 670000 | 43,5-63,5 | 40 | 40 | 10/16 | 4 | 96 | 150 | 65 | 110 | 4,200 |

| 670001 | 43,5-63,5 | 40 | 50 | 10/16 | 4 | 96 | 165 | 65 | 110 | 4,200 |

| 670002 | 48,0-71,0 | 50 | 50 | 10/16 | 4 | 96 | 165 | 65 | 110 | 4,820 |

| 670003 | 63,0-83,7 | 65 | 65 | 10/16 | 4 | 96 | 185 | 65 | 110 | 5,840 |

| 670005 | 85,7-107,0 | 80 | 80 | 10/16 | 2 | 60 | 200 | 65 | 110 | 6,200 |

| 670007 | 107,2-133,2 | 100 | 100 | 10/16 | 2 | 36 | 220 | 90 | 125 | 10,000 |

| 670009 | 132,2-160,2 | 125 | 125 | 10/16 | 2 | 24 | 252 | 90 | 135 | 11,600 |

| 670011 | 158,2-192,2 | 150 | 150 | 10/16 | 1 | 18 | 285 | 90 | 125 | 16,050 |

| 670013 | 192,2-226,9 | 175 | 200 | 10/16 | 1 | 18 | 340 | 125 | 165 | 16,600 |

| 670015 | 218,1-256,0 | 200 | 200 | 10/16 | 1 | 12 | 340 | 125 | 165 | 22,600 |

| 670017 | 266,2-310,2 | 250 | 250 | 10/16 | 1 | 4 | 400 | 125 | 165 | 33,800 |

| 670019 | 315,0-356,0 | 300 | 300 | 10/16 | 1 | 4 | 470 | 125 | 200 | 42,500 |

| 670021 | 352,2-396,0 | 350 | 350 | 10/16 | 1 | 1 | 520 | 125 | 200 | 50,000 |

| 670023 | 398,2-442,0 | 400 | 400 | 10/16 | 1 | 1 | 580 | 125 | 200 | 60,000 |

Areas of application

FRIAGRIP coupling FGK as a restrained coupling1 for pipes made of different materials (steel, cast iron, ductile iron, fiber cement2, PVC3, PE-HD/PEX4). Available from DN 40 to DN 600+.

FRIAGRIP components can only be used in buried areas

Processing instructions

FRIAGRIP, restrained couplings for connections without without abutments (exception: asbestos cement pipes).

The pipe ends must be prepared in accordance with the general installation requirements (see FRIAGRIP installation instructions).

The insertion depths tmin./tmax. must be strictly observed.

1 Restrained; water: ≤ DN 300 PN 16, > DN 300 PN10 / restrained: ≤ DN 400 PN 5.

2 Restrained cannot be guaranteed for asbestos cement pipes

3 For application on PVC gas pipes, see FRIAGRIP Technical Information. For PVC pipes with wall thicknesses DIN 8061/62 - PN 10, use the FRIAGRIP support liners (type FRIATEC Mod. SHVA).

For application on stainless steel pipes, see FRIAGRIP Technical Information.

4 When used with PE-HD/PEX pipes, the FRIAGRIP support liners

Good reasons for FRIAGRIP

- Working in Pipe Trenches reduced to a minimum (no abutments required for directional changes)

- The components are delivered pre-assembled at the factory, thus no conversion and replacement work is required on site

- One gasket-package and one gripping segment for the pipe materials steel, cast iron, ductile iron, fiber cement, PVC, PE-HD/PEX.

- Gasket and gripping system operate independently of each other. This ensures a reliable seal under dynamic axial loads.

- Specially profiled gasket ensures full seal even on scored and corroded pipes.

- Deflection of the pipes up to 8° (coupling) or 4° (flange adapter).

- In case of pipe breakage, axial misalignment can be compensated by installing two couplings. The couplings act like a joint and keep the pipe stress-free

- Simple installation with standard tools

- One torque for all pipe materials

- Repeated checking of the tightening torque of the bolts not necessary

- The tolerance range of up to 54 mm allows different pipe materials to be connected to one FRIAGRIP-Size, therefore reduced stock-keeping necessary

get_app

get_app

get_app

get_app