VKDOAM/CE 24 V AC/DC - Electrically actuated DUAL BLOCK® 2-way ball valve DN 10:50

Electrically actuated DUAL BLOCK® ball valve with ANSI B16.5 cl.150#FF fixed flanges and electric actuator 24 V AC/DC.

FIP has developed a VKD DUAL BLOCK® ball valve to introduce a high reference standard in thermosplastic valve design. VKD is a True Union ball valve that meets the most stringent needs required by industrial applications.

In addition to the manually actuated version, VKD is also available in VKD/CE electrically actuated and VKD/CP pneumatically actuated configurations. Actuators are firmly connected to the valve by the special FIP PowerQuick modules fully made of PP-GR technopolymer. VKD/CE and VKD/CP are constructed with actuators meeting current regulations and selected by FIP according to their quality and reliability requirements. The efficiency of these valves, tested according to the company’s quality standards, is guaranteed by the expertise and know-how that FIP dedicates to manufacturing its products.

Main features:

- Electric actuator constructed according to FIP specifications; with plastic shell and standard emergency override. Available with voltages from 12 to 240V

- Rack & pinion type pneumatic actuator constructed according to FIP specifications: fully protected against weather corrosion available in double-acting (DA) or simple-acting normally closed (NC) or normally open (NO) versions

- DUAL BLOCK® patented lock system that ensures union nut tightening hold even in severe conditions such as vibrations or heat dilation

- Double stem with double O-Rings for ball centring and operating torque reduction. The upper stem is also equipped with a co-moulded steel insert that guarantees high durability and perfect torque transmission between the actuator and ball

EPDM

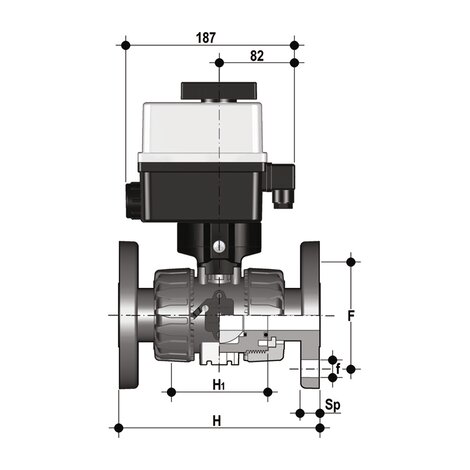

| Reference | system | Category | family | series | d | DN | PN | H | H1 | F | f | U | Sp | B | B1 | g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VKDOAMEL012E | Automation system | Electrically actuated valves | Ball valves | VKD/CE DN 10÷50 | 1/2” | 15 | 10 | 143 | 65 | 60,3 | 15,9 | 4 | 11 | 205 | 29 | 1715 |

| VKDOAMEL034E | Automation system | Electrically actuated valves | Ball valves | VKD/CE DN 10÷50 | 3/4” | 20 | 10 | 172 | 70 | 69,9 | 15,9 | 4 | 14 | 216 | 34.5 | 1791 |

| VKDOAMEL100E | Automation system | Electrically actuated valves | Ball valves | VKD/CE DN 10÷50 | 1” | 25 | 10 | 187 | 78 | 79,4 | 15,9 | 4 | 14 | 221 | 39 | 1871 |

| VKDOAMEL114E | Automation system | Electrically actuated valves | Ball valves | VKD/CE DN 10÷50 | 1” 1/4 | 32 | 10 | 190 | 88 | 88,9 | 15,9 | 4 | 14 | 238 | 46 | 2156 |

| VKDOAMEL112E | Automation system | Electrically actuated valves | Ball valves | VKD/CE DN 10÷50 | 1” 1/2 | 40 | 10 | 212 | 93 | 98,4 | 15,9 | 4 | 16 | 244 | 52 | 2358 |

| VKDOAMEL200E | Automation system | Electrically actuated valves | Ball valves | VKD/CE DN 10÷50 | 2” | 50 | 10 | 234 | 111 | 120,7 | 19,1 | 4 | 16 | 261 | 62 | 2807 |

FKM

| Reference | system | Category | family | series | d | DN | PN | H | H1 | F | f | U | Sp | B | B1 | g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VKDOAMEL012F | Automation system | Electrically actuated valves | Ball valves | VKD/CE DN 10÷50 | 1/2” | 15 | 10 | 143 | 65 | 60,3 | 15,9 | 4 | 11 | 205 | 29 | 1715 |

| VKDOAMEL034F | Automation system | Electrically actuated valves | Ball valves | VKD/CE DN 10÷50 | 3/4” | 20 | 10 | 172 | 70 | 69,9 | 15,9 | 4 | 14 | 216 | 34.5 | 1791 |

| VKDOAMEL100F | Automation system | Electrically actuated valves | Ball valves | VKD/CE DN 10÷50 | 1” | 25 | 10 | 187 | 78 | 79,4 | 15,9 | 4 | 14 | 221 | 39 | 1871 |

| VKDOAMEL114F | Automation system | Electrically actuated valves | Ball valves | VKD/CE DN 10÷50 | 1” 1/4 | 32 | 10 | 190 | 88 | 88,9 | 15,9 | 4 | 14 | 238 | 46 | 2156 |

| VKDOAMEL112F | Automation system | Electrically actuated valves | Ball valves | VKD/CE DN 10÷50 | 1” 1/2 | 40 | 10 | 212 | 93 | 98,4 | 15,9 | 4 | 16 | 244 | 52 | 2358 |

| VKDOAMEL200F | Automation system | Electrically actuated valves | Ball valves | VKD/CE DN 10÷50 | 2” | 50 | 10 | 234 | 111 | 120,7 | 19,1 | 4 | 16 | 261 | 62 | 2807 |

- Joint system for solvent welding (PVC-U and PVC-C only), for welding (PP-H and PVDF only), for threading and flanging

- Patented SEAT STOP® ball carrier system that lets you micro-adjust ball seats and minimise the axial force effect.

- Easy radial disassembly allowing quick replacement of O-rings and ball seats without any need for tools

- Radial dismounting valve body (True Union) made for PVC-U, PVC-C and PP-H injection moulding equipped with built-in bores for actuation. ISO 9393 compliant test requisites

- Option of disassembling downstream pipes with the valve in the closed position

- Floating full bore ball with high surface finish

- Integrated bracket for valve anchoring

- Possibility of installing a gear box or pneumatic and/or electric actuators by applying an ISO standard bore PP-GR flange

- Stainless steel co-moulded stem, with square section as per ISO 5211

get_app

get_app

get_app

get_app