STRAUB-FLEX

All pipe materials can be reliably connected with STRAUB-FLEX couplings.

STRAUB-FLEX pipe couplings enable pipe connections for practically all conceivable pipe diameters, for the same or different types of pipe materials, various media and temperatures as well as for a wide range of the operating pressure values. The sealing sleeve separates the coupling casing from the pipe surface so that sound, vibrations and oscillations are optimally damped.

FLEX 1 ø 48.3 - 168.3 mm

| adMm | Clamping range [mm] | PN industry [bar] | PN shipbuilding [bar] | B [mm] | DV [mm] | C [mm] | X [mm] | R without strip insert [mm] | R with strip insert [mm] | Torque rate [Nm] |

|---|---|---|---|---|---|---|---|---|---|---|

| 48.3 | 47.0 - 50.0 | 25 | 16 | 75 | 70 | 35 | 83 | 5 | 42125 | 7.5 |

| 54 | 52.5 - 55.5 | 25 | 16 | 75 | 76 | 35 | 88 | 5 | 42125 | 7.5 |

| 57 | 55.5 - 58.5 | 25 | 16 | 75 | 79 | 35 | 94 | 5 | 42125 | 7.5 |

| 60.3 | 59.0 - 63.0 | 25 | 16 | 75 | 82 | 35 | 95 | 5 | 42125 | 7.5 |

| 70 | 69.5 - 71.0 | 25 | 16 | 94 | 95 | 51 | 112 | 5 | 45778 | 7.5 |

| 73 | 71.5 - 75.0 | 25 | 16 | 94 | 95 | 51 | 112 | 5 | 45778 | 7.5 |

| 76.1 | 74.5 - 77.5 | 25 | 16 | 94 | 98 | 51 | 119 | 5 | 45778 | 7.5 |

| 80 | 79.5 - 81.5 | 25 | 16 | 94 | 106 | 51 | 127 | 5 | 45778 | 7.5 |

| 84 | 82.5 - 85.5 | 25 | 16 | 94 | 106 | 51 | 127 | 5 | 45778 | 7.5 |

| 88.9 | 87.5 - 90.5 | 25 | 16 | 94 | 111 | 51 | 132 | 5 | 45778 | 7.5 |

| 100.6 | 99.0 - 102.5 | 25 | 16 | 94 | 123 | 51 | 145 | 5 | 45778 | 7.5 |

| 101.6 | 100.0 - 103.5 | 25 | 16 | 94 | 124 | 51 | 145 | 5 | 45778 | 7.5 |

| 104 | 102.5 - 105.5 | 20 | 16 | 94 | 126 | 51 | 146 | 5 | 45778 | 7.5 |

| 104.8 | 103.0 - 106.5 | 20 | 16 | 94 | 127 | 51 | 146 | 5 | 45778 | 7.5 |

| 108 | 106.5 - 110.0 | 20 | 16 | 94 | 130 | 51 | 151 | 5 | 45778 | 7.5 |

| 114.3 | 112.5 - 116.0 | 20 | 16 | 94 | 136 | 51 | 160 | 5 | 45778 | 7.5 |

| 127 | 125.0 - 129.0 | 20 | 16 | 107 | 149 | 62 | 168 | 5 | 12905 | 10 |

| 129 | 127.0 - 131.0 | 20 | 16 | 107 | 151 | 62 | 170 | 5 | 12905 | 10 |

| 130.2 | 128.5 - 132.0 | 20 | 16 | 107 | 152 | 62 | 170 | 5 | 12905 | 10 |

| 133 | 131.0 - 135.0 | 16 | 16 | 107 | 155 | 62 | 174 | 5 | 12905 | 10 |

| 139.7 | 138.0 - 141.5 | 16 | 16 | 107 | 162 | 62 | 180 | 5 | 12905 | 10 |

| 141.3 | 139.5 - 143.0 | 16 | 16 | 107 | 163 | 62 | 182 | 5 | 12905 | 10 |

| 154 | 152.0 - 156.0 | 16 | 16 | 107 | 176 | 62 | 198 | 5 | 12905 | 10 |

| 159 | 157.0 - 161.0 | 16 | 16 | 107 | 181 | 62 | 203 | 5 | 12905 | 10 |

| 168.3 | 166.0 - 170.5 | 16 | 16 | 107 | 190 | 62 | 212 | 5 | 12905 | 10 |

Remarks:

-Follow fitting instructions

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- Burst pressure = approx. PN (Industry) x 2

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding) Strip inserts are optional accessories

- Additional sealing sleeves, pressure and temperature ranges on request

- FPM / FKM only available as STRAUB-OPEN-FLEX

-Follow fitting instructions

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- Burst pressure = approx. PN (Industry) x 2

- PN (Shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding) Strip inserts are optional accessories

- Additional sealing sleeves, pressure and temperature ranges on request

- FPM / FKM only available as STRAUB-OPEN-FLEX

FLEX 2 ø 172.0 - 2032.0 mm

| adMm | Clamping range [mm] | PN Industry [bar] 25 | PN Industry [bar] 6 | PN Industry [bar] 10 | PN Industry [bar] 16 | PN Industry [bar] 20 | PN Industry [bar] 2.5 |

|---|---|---|---|---|---|---|---|

| 172 | 170 - 174 | W2 | W5 | W2 | W5 | W2 | W5 | - | - | - |

| 180 | 178 - 182 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 |

| 200 | 198 - 202 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 |

| 219.1 | 217 - 222 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 |

| 250 | 248 - 253 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 |

| 267 | 264 - 270 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 |

| 273 | 270 - 276 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W2 | W5 |

| 304 | 301 - 307 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 |

| 323.9 | 321 - 327 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 |

| 355.6 | 353 - 358 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 |

| 406.4 | 404 - 409 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 |

| 457.2 | 454 - 460 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 508 | 505 - 511 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 558.8 | 556 - 562 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 |

| 609.6 | 606 - 613 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 |

| 711.2 | 708 - 715 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W1 |

| 762 | 758 - 766 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W1 |

| 812.8 | 809 - 817 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | - |

| 914.4 | 910 - 918 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W1 | - |

| 1016 | 1012 - 1020 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W1 | - |

| 1117.6 | 1114 - 1122 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | - | - |

| 1219.2 | 1215 - 1224 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | - | - |

| 1320.8 | 1316 - 1325 | W1 | W2 | W5 | W1 | W5 | W1 | W1 | - | - |

| 1422.4 | 1418 - 1427 | W1 | W2 | W5 | W1 | W5 | W1 | W1 | - | - |

| 1524 | 1519 - 1529 | W1 | W2 | W5 | W1 | W5 | W1 | W1 | - | - |

| 1600 | 1595 - 1605 | W1 | W2 | W5 | W1 | W5 | W1 | - | - | - |

| 1625.6 | 1621 - 1631 | W1 | W2 | W5 | W1 | W5 | W1 | - | - | - |

| 1727.2 | 1722 - 1732 | W1 | W2 | W5 | W1 | W5 | W1 | - | - | - |

| 1828.8 | 1824 - 1834 | W1 | W2 | W5 | W1 | W5 | W1 | - | - | - |

| 1930.4 | 1925 - 1935 | W1 | W2 | W5 | W1 | W5 | W1 | - | - | - |

| 2032 | 2027 - 2037 | W1 | W2 | W5 | W1 | W5 | W1 | - | - | - |

Remarks:

- Follow fitting instructions

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- Burst pressure = approx. PN ( ) x 2

- PN (shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- Strip inserts are optional accessories (see page 87)

- Additional sealing sleeves, pressure and temperature ranges on request

- Follow fitting instructions

- PN (Industry) = working pressure considering the application loads

- Test pressure = PN (Industry) x 1.5 (for example industry, water supply etc.)

- Burst pressure = approx. PN ( ) x 2

- PN (shipbuilding) = nominal pressure, includes four times safety factor (e.g. shipbuilding)

- Strip inserts are optional accessories (see page 87)

- Additional sealing sleeves, pressure and temperature ranges on request

FLEX 3 ø 219.1 - 2032.0 mm

| adMm | Clamping range [mm] | PN Industry [bar] 25 | PN Industry [bar] 6 | PN Industry [bar] 10 | PN Industry [bar] 16 | PN Industry [bar] 20 | PN Industry [bar] 2.5 |

|---|---|---|---|---|---|---|---|

| 219.1 | 216 - 222 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | - | - |

| 250 | 247 - 253 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W1 | W5 | W1 | W5 |

| 267 | 264 - 270 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W1 | W5 | W1 | W5 |

| 273 | 270 - 276 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W1 | W5 | W1 | W5 |

| 304 | 301 - 307 | W2 | W5 | W2 | W5 | W2 | W5 | W2 | W5 | W1 | W5 | W1 | W5 |

| 323.9 | 321 - 327 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 |

| 355.6 | 352 - 358 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 406.4 | 403 - 409 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 457.2 | 454 - 460 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 508 | 504 - 512 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5* |

| 558.8 | 555 - 562 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5* |

| 609.6 | 606 - 613 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5* |

| 711.2 | 707 - 715 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5* | W1 | W5* |

| 762 | 758 - 766 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5* | W1 | W5* |

| 812.8 | 809 - 817 | W1 | W2 | W5 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5* | W1 | W5* |

| 914.4 | 910 - 918 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5* | W1 | W5* | W1 | W5* |

| 1016 | 1012 - 1020 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5* | W1 | W5* | W1* |

| 1117.6 | 1113 - 1122 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5* | W1 | W5* | W1* |

| 1219.2 | 1215 - 1224 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5* | W1* | W1* |

| 1320.8 | 1316 - 1325 | W1 | W2 | W5 | W1 | W5 | W1 | W5 | W1 | W5* | W1* | W1* |

| 1422.4 | 1418 - 1427 | W1 | W2 | W5 | W1 | W5 | W1 | W5* | W1 | W5* | W1* | - |

| 1524 | 1519 - 1529 | W1 | W2 | W5 | W1 | W5 | W1 | W5* | W1* | W1* | - |

| 1600 | 1595 - 1605 | W1 | W2 | W5 | W1 | W5 | W1 | W5* | W1* | W1* | - |

| 1625.6 | 1621 - 1631 | W1 | W2 | W5 | W1 | W5 | W1 | W5* | W1* | W1* | - |

| 1727.2 | 1722 - 1732 | W1 | W2 | W5 | W1 | W5 | W1 | - | - | - |

| 1828.8 | 1824 - 1834 | W1 | W2 | W5 | W1 | W5 | W1 | - | - | - |

| 1930.4 | 1925 - 1935 | W1 | W2 | W5 | W1 | W5 | W1 | - | - | - |

| 2032 | 2027 - 2037 | W1 | W2 | W5 | W1 | W5 | W1 | - | - | - |

Remarks:

- Follow fitting instructions

- PN = working pressure considering the application loads

- Test pressure = PN x 1.5 (for example industry, water supply etc.)

- Burst pressure = approx. PN x 2

- Strip inserts included

- Additional sealing sleeves, pressure and temperature ranges on request

* These products are only available on request

- Follow fitting instructions

- PN = working pressure considering the application loads

- Test pressure = PN x 1.5 (for example industry, water supply etc.)

- Burst pressure = approx. PN x 2

- Strip inserts included

- Additional sealing sleeves, pressure and temperature ranges on request

* These products are only available on request

FLEX 3.5 ø 323.9 - 1219.2 mm

| adMm | Clamping range [mm] | PN Industry [bar] 25 | PN Industry [bar] 6 | PN Industry [bar] 10 | PN Industry [bar] 16 | PN Industry [bar] 20 | PN Industry [bar] 2.5 |

|---|---|---|---|---|---|---|---|

| 323.9 | 320 - 327 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 355.6 | 352 - 359 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 406.4 | 402 - 410 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 457.2 | 453 - 461 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 508 | 504 - 512 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 558.8 | 555 - 563 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W5* |

| 609.6 | 605 - 614 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W5* |

| 655 | 651 - 659 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W5* | W5* |

| 711.2 | 707 - 715 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W5* | W5* |

| 762 | 758 - 766 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W5* | W5* |

| 812.8 | 809 - 817 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W5* | W5* |

| 914.4 | 910 - 918 | W1 | W5 | W1 | W5 | W1 | W5 | W5* | W5* | W5* |

| 1016 | 1011 - 1021 | W1 | W5 | W1 | W5 | W1 | W5 | W5* | W5* | - |

| 1117.6 | 1112 - 1123 | W1 | W5 | W1 | W5 | W1 | W5 | W5* | W5* | - |

| 1219.2 | 1214 - 1224 | W1 | W5 | W1 | W5 | W1 | W5 | W5* | - | - |

Remarks:

- Follow fitting instructions

- PN = working pressure considering the application loads

- Test pressure = PN x 1.5 (for example industry, water supply etc.)

- Burst pressure = approx. PN x 2

- Strip inserts included

- Additional sealing sleeves, pressure and temperature ranges on request

* These products are only available on request

- Follow fitting instructions

- PN = working pressure considering the application loads

- Test pressure = PN x 1.5 (for example industry, water supply etc.)

- Burst pressure = approx. PN x 2

- Strip inserts included

- Additional sealing sleeves, pressure and temperature ranges on request

* These products are only available on request

FLEX 4 ø 323.9 - 812.8 mm

| adMm | Clamping range [mm] | PN Industry [bar] 25 | PN Industry [bar] 6 | PN Industry [bar] 10 | PN Industry [bar] 16 | PN Industry [bar] 20 | PN Industry [bar] 2.5 |

|---|---|---|---|---|---|---|---|

| 323.9 | 320 - 327 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 355.6 | 352 - 359 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 406.4 | 403 - 409 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 457.2 | 454 - 460 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 |

| 508 | 505 - 512 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5* |

| 558.8 | 555 - 562 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W5* |

| 609.6 | 606 - 613 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W5* |

| 655 | 652 - 658 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W5* | W5* |

| 711.2 | 707 - 715 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W5* | W5* |

| 762 | 758 - 766 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W5* | W5* |

| 812.8 | 809 - 817 | W1 | W5 | W1 | W5 | W1 | W5 | W1 | W5 | W5* | W5* |

Remarks:

- Follow fitting instructions

- PN = working pressure considering the application loads

- Test pressure = PN x 1.5 (for example industry, water supply etc.)

- Burst pressure = approx. PN x 2

- Strip inserts included

- Additional sealing sleeves, pressure and temperature ranges on request

* These products are only available on request

- Follow fitting instructions

- PN = working pressure considering the application loads

- Test pressure = PN x 1.5 (for example industry, water supply etc.)

- Burst pressure = approx. PN x 2

- Strip inserts included

- Additional sealing sleeves, pressure and temperature ranges on request

* These products are only available on request

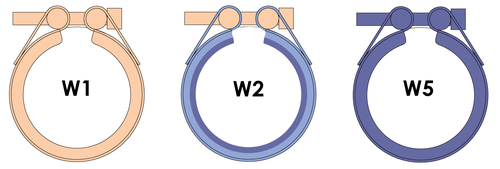

STRAUB pipe couplings are made of the same or different materials depending on the diameter and size. The following overview shows the details. If you have any questions, please contact our application technology department.

FLEX 1 ø 48.3 - 168.3 mm

| Components | W1 | W2 | W5 |

|---|---|---|---|

| - | AISI 316 L or similar | AISI 316 L or similar | |

| - | AISI 4135 | A4 - 80 | |

| - | AISI 12L14, galvanised | AISI 316 L or similar | |

| - | AISI 316 L or similar / PVDF | AISI 316 L or similar / PVDF |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|

FLEX 2 ø 172.0 - 2032.0 mm

| Components | W1 | W2 | W5 |

|---|---|---|---|

| S355MC, hot-dip galvanised | AISI 316 L or similar | AISI 316 L or similar | |

| AISI 4135 | AISI 4135 | A4 - 80 | |

| AISI 12L14, galvanised | AISI 12L14, galvanised | AISI 316 L or similar | |

| AISI 316 L or similar / HDPE | AISI 316 L or similar / HDPE | AISI 316 L or similar / HDPE |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|

FLEX 3 ø 219.1 - 2032.0 mm

| Components | W1 | W2 | W5 |

|---|---|---|---|

| S355MC, hot-dip galvanised | AISI 316 L or similar | AISI 316 L or similar | |

| AISI 4135 | AISI 4135 | A4 - 80 | |

| AISI 12L14, galvanised | AISI 12L14, galvanised | AISI 316 L or similar | |

| AISI 316 L or similar / HDPE | AISI 316 L or similar / HDPE | AISI 316 L or similar / HDPE |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|

FLEX 3.5 ø 323.9 - 1219.2 mm

| Components | W1 | W2 | W5 |

|---|---|---|---|

| S355MC, hot-dip galvanised | - | S32101 (LDX) | |

| AISI 4135 | - | A4 - 80 | |

| AISI 12L14, galvanised | - | AISI 316 L or similar | |

| AISI 316 L or similar / HDPE | - | AISI 316 L or similar / HDPE |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|

FLEX 4 ø 323.9 - 812.8 mm

| Components | W1 | W2 | W5 |

|---|---|---|---|

| S355MC, hot-dip galvanised | - | S32101 (LDX) | |

| AISI 4135 | - | A4 - 80 | |

| AISI 12L14, galvanised | - | AISI 316 L or similar | |

| AISI 301 / HDPE | - | AISI 316 L or similar / HDPE |

| Sealing sleeve | Temperatur | Medium |

|---|---|---|