|

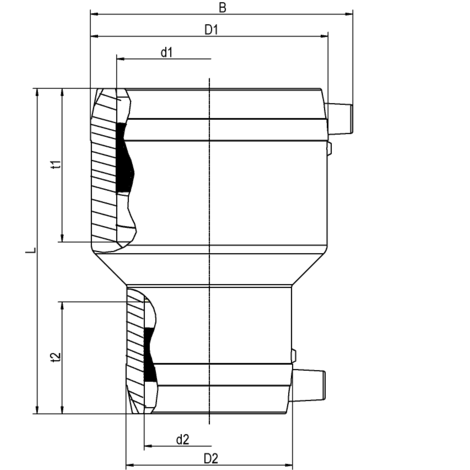

616824

|

20

|

16

|

1

|

2240

|

36

|

36

|

44

|

28

|

0,040

|

|

616452

|

32

|

16

|

80

|

2560

|

39

|

34

|

62

|

28

|

0,080

|

|

615386

|

32

|

20

|

90

|

2880

|

39

|

30

|

62

|

32

|

0,070

|

|

615502

|

32

|

25

|

80

|

2560

|

39

|

33

|

62

|

38

|

0,080

|

|

615387

|

40

|

20

|

60

|

1920

|

43

|

30

|

70

|

32

|

0,090

|

|

616751

|

40

|

25

|

1

|

1280

|

50

|

40

|

66

|

38

|

0,090

|

|

615388

|

40

|

32

|

50

|

1600

|

43

|

39

|

70

|

45

|

0,100

|

|

616752

|

50

|

25

|

1

|

960

|

52

|

39

|

77

|

38

|

0,120

|

|

612070

|

50

|

32

|

32

|

1024

|

49

|

39

|

82

|

45

|

0,150

|

|

612071

|

50

|

40

|

25

|

800

|

49

|

43

|

82

|

54

|

0,150

|

|

615389

|

63

|

32

|

20

|

640

|

55

|

44

|

96

|

45

|

0,210

|

|

615390

|

63

|

40

|

16

|

512

|

55

|

43

|

96

|

54

|

0,230

|

|

612072

|

63

|

50

|

16

|

512

|

55

|

48

|

96

|

68

|

0,230

|

|

616583

|

75

|

63

|

15

|

270

|

61

|

55

|

110

|

79

|

0,300

|

|

615391

|

90

|

50

|

15

|

270

|

69

|

49

|

129

|

68

|

0,480

|

|

615392

|

90

|

63

|

15

|

270

|

69

|

55

|

129

|

82

|

0,510

|

|

616582

|

90

|

75

|

15

|

270

|

67

|

63

|

127

|

94

|

0,510

|

|

615393

|

110

|

63

|

10

|

180

|

79

|

55

|

152

|

82

|

0,730

|

|

615693

|

110

|

90

|

8

|

144

|

79

|

69

|

152

|

115

|

0,880

|

|

615694

|

125

|

90

|

8

|

144

|

86

|

69

|

166

|

115

|

0,990

|

|

616510

|

125

|

110

|

16

|

128

|

95

|

70

|

172

|

137

|

1,160

|

|

615695

|

160

|

110

|

8

|

64

|

98

|

79

|

207

|

140

|

2,000

|

|

616511

|

180

|

125

|

1

|

60

|

108

|

74

|

230

|

155

|

2,300

|

|

616356

|

225

|

160

|

1

|

36

|

110

|

98

|

283

|

203

|

4,860

|