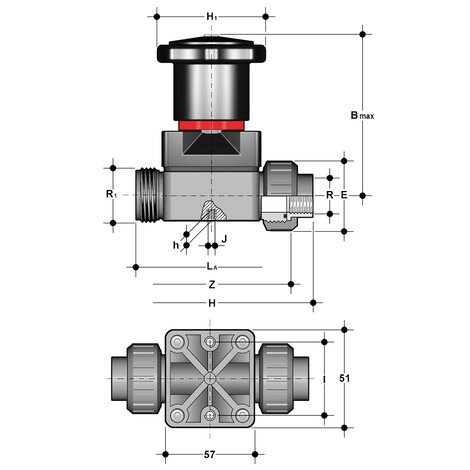

CMUFV - Compact diaphragm valve DN 12:15

Compact diaphragm valve with BSP threaded female union ends unions.

The CM is a manually operated diaphragm valve of reduced dimensions and particularly compact structure, ideal for use in confined spaces.

Main features:

- Handwheel in PA-GR, completely sealed, high mechanical strength with ergonomic grip for optimum manageability

- Integrated adjustable torque limiter designed to prevent excessive compression of the diaphragm and always guarantee a minimum fluid flow

- Optical position indicator supplied as standard

- Bonnet in PA-GR with STAINLESS steel nuts fully protected by plastic plugs to eliminate zones where impurities may accumulate. Internal circular and symmetrical diaphragm sealing area

- STAINLESS steel bolts, can also be inserted from above

- Threaded metal inserts for anchoring the valve

EPDM

| Reference | system | Category | family | series | R | DN | PN | B max | E | H | H1 | h | I | J | La | R1 | Z | g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CMUFV012E | PVC-U system | Manual valves | Diaphragm valves | CM DN 12÷15 | 1/2” | 15 | 6 | 86 | 41 | 129,5 | 58,5 | 8 | 35 | M5 | 90 | 1” | 97,5 | 285 |

FKM

| Reference | system | Category | family | series | R | DN | PN | B max | E | H | H1 | h | I | J | La | R1 | Z | g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CMUFV012F | PVC-U system | Manual valves | Diaphragm valves | CM DN 12÷15 | 1/2” | 15 | 6 | 86 | 41 | 129,5 | 58,5 | 8 | 35 | M5 | 90 | 1” | 97,5 | 285 |

PTFE

| Reference | system | Category | family | series | R | DN | PN | B max | E | H | H1 | h | I | J | La | R1 | Z | g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CMUFV012P | PVC-U system | Manual valves | Diaphragm valves | CM DN 12÷15 | 1/2” | 15 | 6 | 86 | 41 | 129,5 | 58.5 | 8 | 35 | M5 | 90 | 1” | 97,5 | 285 |

- Connection system for solvent weld and threaded joints

- Extremely compact construction

- Internal operating components in metal totally isolated from the conveyed fluid

- Valve stem in STAINLESS steel

- Compressor with floating diaphragm support

- Easy to replace diaphragm seal

- Corrosion-proof internal components

- CDSA (Circular Diaphragm Sealing Angle) system offering the following advantages:

- uniform distribution of shutter pressure on the diaphragm seal

- reduction in the tightening torque of the crews fixing the actuator to the valve body

- reduced mechanical stress on all valve components (actuator, body and diaphragm)

- easy to clean valve interior

- low risk of the accumulation of eposits, contamination or damage to the diaphragm due to crystallisation

- operating torque reduction

get_app

get_app

get_app

get_app