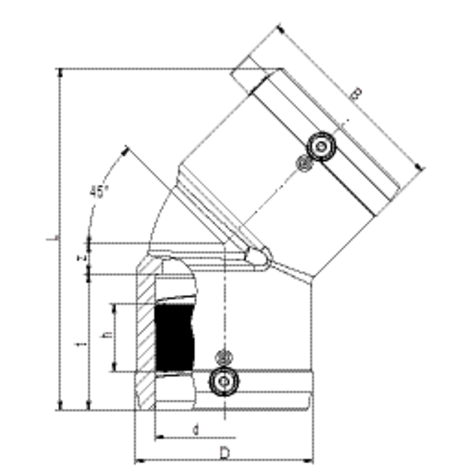

Elbow 45°, SDR 11

Elbow W45 SDR 11

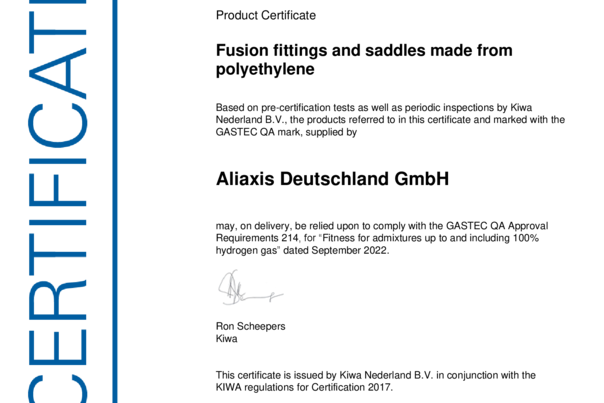

- Gas, water and H2

- Working pressure: MOP (gas) 10 bar, PFA (water) 16 bar

- Material: PE 100

- Angle 45 degrees

- Safety technology

- DVGW test mark: DV-8601AU2248, DV-8606AU2249 and DV-8611AU2250

- FM Approvals Class: 1613 (d 63 - d 225)

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water) / 10 bar (gas)

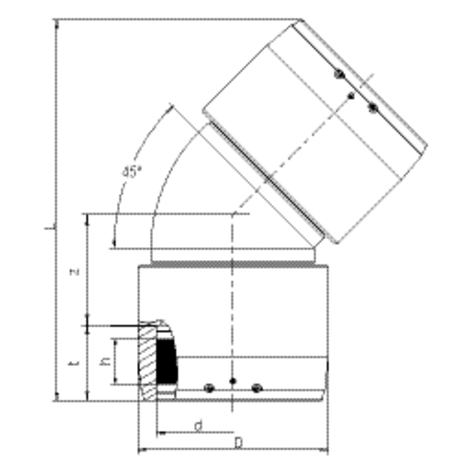

| Reference | d | BX | PU | D | t | z | h | B | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|

| 616687 | 25 | 150 | 2400 | 35 | 38 | 7 | 17 | 48 | 0,050 |

| 612092 | 32 | 50 | 1600 | 43 | 44 | 8 | 21 | 60 | 0,070 |

| 612094 | 40 | 30 | 960 | 54 | 49 | 11 | 29 | 70 | 0,120 |

| 612096 | 50 | 20 | 640 | 66 | 54 | 13 | 32 | 80 | 0,180 |

| 612098 | 63 | 10 | 320 | 82 | 62 | 14 | 34 | 95 | 0,290 |

| 612100 | 75 | 30 | 240 | 96 | 70 | 29 | 38 | 111 | 0,520 |

| 612102 | 90 | 18 | 144 | 115 | 79 | 35 | 45 | 128 | 0,810 |

| 612104 | 110 | 10 | 80 | 138 | 85 | 41 | 50 | 150 | 1,320 |

| 612106 | 125 | 10 | 80 | 157 | 87 | 46 | 44 | 167 | 1,800 |

| 615275 | 160 | 4 | 32 | 207 | 92 | 88 | 44 | 210 | 4,280 |

| 615687 | 180 | 3 | 24 | 228 | 97 | 83 | 65 | 229 | 4,600 |

| 616264 | 200 | 2 | 16 | 254 | 106 | 87 | 54 | 256 | 6,590 |

| 615688 | 225 | 1 | 8 | 280 | 112 | 98 | 66 | 281 | 8,300 |

| 616404 | 250 | 1 | 6 | 310 | 128 | 176 | 80 | - | 17,300 |

| 616405 | 280 | 1 | 4 | 350 | 139 | 205 | 84 | - | 25,600 |

| 616406 | 315 | 1 | 2 | 396 | 150 | 215 | 80 | - | 35,270 |

FRIALEN safety fittings can be fused with SDR11 - SDR17.6 pipes. For W 45 > d 225 separate fusion zones per socket side.

Minimum wall thickness s minimum ≥ 3 mm.

Other levels of SDR can be processed on request.

Please note the mandatory labels directly on the product.

DVGW test marks issued: DV-8601AU2248, DV-8606AU2249 and DV-8611AU2250

Areas of Application

The FRIALEN-Elbow W45° is used for all changes of direction in HD-PE pipes.

Assembly Instructions

The fusion of the pipe ends with the FRIALEN-Elbows W45° takes place by FRIALEN-fusing – leakproof and longitudinally strong.

The pipe ends are prepared according to the general installation instructions (see Assembly Instructions for FRIALEN-Safety Fittings for house connections and distribution pipes up to d 225). This involves removing the oxide skin and cleaning the pipe ends.

Good reasons for using the FRIALEN-Elbows W45°:

- Large coupler depth for ease of pipe guiding (no holding clamps required)

- Extra wide fusion zones

- Maximum stability through great wall thickness

- Cold zones at the front side and in the middle of the coupler

- Exposed heating coil for direct heat transmission to the pipe

- Small annular gap for build-up of optimum joining pressure in the fusion zone

- Contacts safe to touch

- Fusion indicator for visual fusion control

- Durable batch marking

- Individually wrapped for dirt protection

- Additional barcode for tracing back the fitting (Traceability-Coding)

get_app

get_app

get_app

get_app